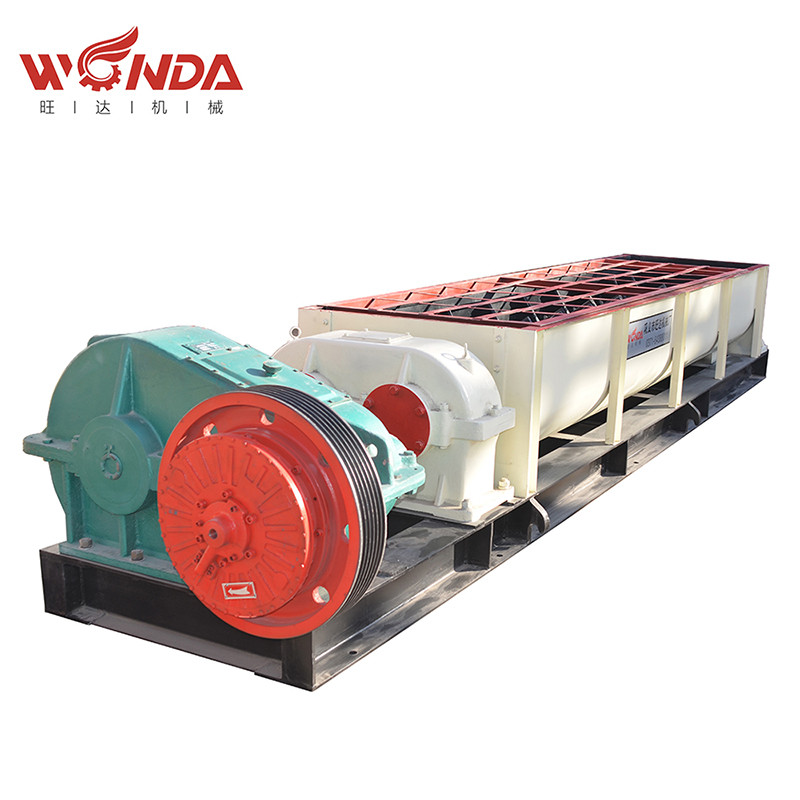

Top Quality Brick Plant Machine for Efficient Production

By:Admin

The brand new brick plant machine, developed by a team of experienced engineers and designers, is the result of years of research and development. It combines the latest technology and innovative design to deliver a cutting-edge solution for brick production. With a focus on sustainability and environmental responsibility, the machine is designed to minimize energy consumption and waste production, making it an ideal choice for modern, eco-friendly manufacturing facilities.

The company behind this groundbreaking machine, with its decades of experience and expertise in the construction and manufacturing industry, has a proven track record of delivering high-quality, reliable, and efficient solutions to its clients. With a commitment to innovation and continuous improvement, the company has established itself as a trusted partner for businesses looking to enhance their production processes and achieve better results.

The new brick plant machine is set to make a significant impact on the industry, offering numerous benefits to its users. One of the key features of the machine is its high production capacity, allowing for the rapid manufacturing of large quantities of bricks to meet the demands of various construction projects. This will enable construction companies and manufacturers to streamline their operations and deliver projects on time and within budget.

In addition to its high production capacity, the machine also boasts superior quality control capabilities, ensuring that every brick produced meets the highest standards of durability and consistency. This will help to reduce the likelihood of defects and ensure that the end products meet the specifications and requirements of clients and regulatory authorities.

Furthermore, the new brick plant machine is designed for ease of use and maintenance, featuring intuitive controls and user-friendly interfaces. This will allow operators to quickly familiarize themselves with the machine and carry out routine maintenance tasks with minimal downtime, maximizing productivity and minimizing operational costs.

With sustainability being a key focus in today's manufacturing sector, the new brick plant machine has been designed with environmental considerations in mind. It incorporates energy-efficient components and processes, minimizing its carbon footprint and reducing overall resource consumption. This aligns with the company's commitment to environmental stewardship and its efforts to support sustainable manufacturing practices.

The launch of the new brick plant machine represents a significant milestone for the company, solidifying its position as a leader in the construction and manufacturing industry. By introducing this cutting-edge solution to the market, the company is demonstrating its dedication to innovation and its ability to address the evolving needs of its clients.

Overall, the introduction of the new brick plant machine is set to have a positive impact on the industry, offering a range of benefits to its users and contributing to the advancement of sustainable and efficient manufacturing practices. With its high production capacity, superior quality control, ease of use and maintenance, and environmental considerations, the machine is poised to become a game-changer in the production of bricks, setting a new standard for the industry as a whole.

Company News & Blog

Compact Clay Brick Making Machine for Efficient Production at Small Scale

Small Clay Brick Making Machine Revolutionizes the Brick Making Industry In a world where construction is a booming industry, the demand for high-quality building materials is insatiable. One essential building material that is in constant demand is bricks. Bricks are the basic building blocks for any construction project, from homes to commercial buildings, and even roads. With the increased demand for bricks, the need for efficient and cost-effective brick making machines has become more apparent.In response to this growing demand, a leading machinery manufacturing company has introduced a revolutionary Small Clay Brick Making Machine. This innovative machine has the capacity to produce high-quality bricks at a fraction of the cost and in a significantly shorter time compared to traditional methods.The Small Clay Brick Making Machine is designed to be compact and portable, making it ideal for small to medium-sized brick-making businesses. It is capable of producing a wide range of brick sizes and shapes, giving users the flexibility to meet the needs of various construction projects. This versatility sets it apart from other brick making machines on the market.The machine's compact design also means that it requires minimal space for operation and can be easily transported to different work sites. This is a game-changer for small-scale brick-making businesses looking to expand their operations or for larger companies wanting to streamline their production processes.One of the most impressive features of the Small Clay Brick Making Machine is its efficiency. It is capable of producing up to 10,000 bricks per hour, significantly increasing productivity and reducing labor costs. This is a huge advantage for brick manufacturers looking to meet tight project deadlines without compromising on the quality of their product.In addition to its high production capacity, the Small Clay Brick Making Machine also boasts a user-friendly interface, making it easy to operate and maintain. This means that even those with limited experience in the brick-making industry can quickly learn how to use the machine and start producing high-quality bricks in no time.The introduction of this Small Clay Brick Making Machine is a testament to the company's commitment to innovation and excellence in the machinery manufacturing industry. With over 20 years of experience in the field, the company has continuously strived to develop cutting-edge solutions to meet the evolving needs of its customers. This latest addition to their product line is a prime example of their dedication to providing practical and efficient solutions for the construction industry.Furthermore, the company prides itself on its unwavering commitment to quality and customer satisfaction. Each Small Clay Brick Making Machine undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of performance and reliability. Additionally, the company provides comprehensive technical support and training to its customers, ensuring that they can maximize the potential of the machine and achieve optimal results.The impact of the Small Clay Brick Making Machine on the brick-making industry is already being felt, with many businesses reporting significant increases in productivity and cost savings. As word spreads about the efficiency and reliability of this innovative machine, it is expected to become a staple in brick-making operations around the world.In conclusion, the introduction of the Small Clay Brick Making Machine marks a significant milestone in the brick-making industry. Its compact design, high production capacity, and user-friendly interface are revolutionizing the way bricks are produced, offering a cost-effective and efficient solution for brick manufacturers of all sizes. As the demand for high-quality building materials continues to grow, this innovative machine is poised to play a pivotal role in meeting the needs of construction projects around the world. With its unwavering commitment to quality and customer satisfaction, the company behind this groundbreaking machine is set to shape the future of the brick-making industry.

Ultimate Guide to Clay Brick Plant: Production, Process and Applications

The Clay Brick Plant, located in (insert location), is a state-of-the-art facility that has been producing high-quality clay bricks for over 20 years. With a focus on innovation and sustainability, the plant has become a leader in the industry and is continuously working towards reducing its environmental impact.The plant utilizes the latest technology and equipment to ensure that the clay bricks produced are of the highest quality. The production process begins with the extraction of raw materials from the surrounding area, which are then carefully processed and molded into bricks. The plant is able to produce a wide range of bricks, including standard bricks, pavers, and specialized bricks for specific architectural needs.In addition to producing high-quality bricks, the plant is also committed to sustainability. This includes implementing energy-efficient practices, recycling waste materials, and minimizing water usage. The plant is also constantly researching and implementing ways to reduce its carbon footprint and overall environmental impact. By prioritizing sustainability, the plant is able to not only produce high-quality bricks, but also to do so in a way that is environmentally responsible.The Clay Brick Plant is a major employer in the area, providing stable jobs for a large number of local residents. The plant also plays an important role in supporting the local economy by sourcing raw materials from local suppliers and contributing to the overall growth of the community.As a leader in the industry, the plant is also committed to ongoing research and development. This includes investing in new technologies and processes to further improve the quality of its bricks and reduce its environmental impact. By staying at the forefront of innovation, the plant is able to stay competitive in the market and continue to meet the needs of its customers.With a focus on quality, sustainability, and innovation, the Clay Brick Plant has established itself as a leader in the industry. Its commitment to producing high-quality bricks in an environmentally responsible manner has set it apart from its competitors and has made it a trusted name in the construction industry.In conclusion, the Clay Brick Plant is a shining example of a company that is able to balance quality, sustainability, and innovation. With a focus on producing high-quality bricks while also minimizing its environmental impact, the plant has become a leader in the industry and a trusted name in the construction market. As it continues to invest in new technologies and processes, the plant is well-positioned to remain a leader in the industry for many years to come.

Revolutionary Hydraulic Block Machine: Significant Advancements in Construction Technology Revealed

Hydraulic Block Machine Revolutionizes Construction IndustryInnovation has always been at the forefront of the construction industry. From the invention of the wheel to the development of concrete, new technologies have constantly pushed the boundaries of what is possible in building construction. Today, a new breakthrough technology, the hydraulic block machine, promises to revolutionize the way we build structures.The hydraulic block machine, manufactured by a renowned company specializing in construction equipment, has gained significant attention for its ability to effortlessly produce high-quality concrete blocks. With this technology, construction companies can now streamline their processes, reduce costs, and improve overall efficiency in the construction of buildings and infrastructure.One of the key features of the hydraulic block machine is its use of hydraulic pressure to compress the concrete mixture into precise and durable blocks. The machine is equipped with a hydraulic system that applies pressure to the raw materials, ensuring optimal compactness and strength in the finished product. This results in blocks that are resistant to cracking, water absorption, and other common issues that can compromise the integrity of a structure.To further enhance the efficiency of the machine, it is equipped with an automated control system that eliminates the need for manual intervention during the block-making process. This eliminates human error and allows for consistent production without compromising on quality. Moreover, the machine is designed to be user-friendly, with an intuitive interface that allows operators to easily set parameters and monitor the production process.The versatility of the hydraulic block machine is another commendable aspect. It can produce a wide range of concrete blocks, including solid, hollow, interlocking, and paver blocks, catering to diverse construction needs. This flexibility makes it an ideal choice for small-scale projects, as well as large-scale commercial and infrastructural developments.One of the main advantages of using the hydraulic block machine is the significant reduction in construction time and cost. Compared to traditional methods of block-making, which require the use of molds, the hydraulic block machine eliminates the need for molds altogether. This not only saves time and labor costs associated with mold production but also reduces material waste. It also eliminates the need for skilled technicians to manufacture and maintain molds, further reducing the overall cost of production.Furthermore, the hydraulic block machine is highly energy-efficient. It utilizes advanced hydraulic technology, which minimizes energy consumption during operation. This not only contributes to a greener environment but also lowers operational costs, making it a cost-effective solution for construction companies.The company behind this groundbreaking technology has been at the forefront of innovation in the construction industry for many years. With a rich history of producing reliable and efficient equipment, they have established themselves as a trusted and reputable manufacturer. They have a strong focus on research and development, constantly striving to improve their products and meet the evolving needs of the industry.In conclusion, the hydraulic block machine presents a game-changing solution for the construction industry. Its ability to produce high-quality concrete blocks with precision and efficiency has the potential to revolutionize the way we build. The technological advancements in this machine, coupled with the company's dedication to innovation, are sure to pave the way for a more efficient and sustainable construction future.

Affordable Interlocking Soil Block Press Machines for Stabilized Construction in Africa

: The Affordable Solution for Building in AfricaIn Africa, especially in rural areas, access to safe and affordable housing remains a significant challenge. The high cost of building materials, combined with inadequate infrastructure and limited resources, makes it difficult for many people to construct reliable homes. However, Makiga Engineering Services Ltd offers an affordable solution to this problem with their Interlocking Stabilized Soil Blocks Press Machines.Interlocking Stabilized Soil Blocks (ISSBs) are compressed and stabilized earth blocks that require no mortar, offering a sustainable and cost-effective alternative to traditional construction materials. The ISSBs are made from a mixture of soil, cement, and water, and are compressed using the Makiga Interlocking Blocks Machine. The machine, available in both electric and manual models, makes high-quality blocks that are structurally sound, durable, and environmentally friendly.One of the benefits of using the Makiga Interlocking Blocks Machine is its affordability. The machine is easy to operate and requires minimal maintenance, making it an ideal investment for small-scale entrepreneurs, community groups, and individuals looking to construct homes or businesses. It eliminates the need for expensive construction materials, such as bricks and timber, while still producing high-quality blocks that meet international standards.Moreover, ISSBs save time and labor costs as they can be easily stacked together without the need for skilled labor or specialized equipment. This makes them an ideal solution for community-based construction projects where resources are limited.Another advantage of working with Makiga Engineering Services Ltd is their dedication to providing comprehensive support services. They offer training on how to use the Interlocking Blocks Machine, as well as technical assistance and after-sales support. This helps to ensure that the blocks produced are of the highest quality, and that the finished structures are structurally sound, aesthetically pleasing, and sustainable.In conclusion, Makiga Engineering Services Ltd's Interlocking Stabilized Soil Blocks Press Machines offer a viable solution to Africa's affordable housing crisis. They provide an affordable, sustainable, and environmentally friendly alternative to traditional construction materials, while also creating opportunities for small-scale entrepreneurs and community-based construction projects to thrive. The Makiga Interlocking Blocks Machine is an investment in the future, offering long-lasting benefits for individuals and communities alike.

Ultimate Guide to Interlocking Bricks Machine Price: Everything You Need to Know

Interlocking bricks are a popular alternative to traditional bricks in the construction industry due to their strength, durability, and cost-effectiveness. These bricks are designed to fit together like puzzle pieces, providing a strong and stable structure that can withstand the test of time. With the growing demand for interlocking bricks, the need for efficient and reliable interlocking bricks machines has also increased.One company that has been making waves in the interlocking bricks machine industry is {}. With years of experience and expertise in the field, they have been able to develop high-quality machines that are not only efficient but also cost-effective. Their interlocking bricks machines are designed to produce bricks of various sizes and designs, making them suitable for a wide range of construction projects.One of the key factors that set {} apart from other interlocking bricks machine manufacturers is their competitive pricing. Despite offering top-of-the-line machines, they have managed to keep their prices competitive, making their machines accessible to a wide range of customers. This has made them a popular choice among both large construction companies and smaller businesses looking to invest in interlocking bricks production.The pricing of interlocking bricks machines from {} is based on various factors, including the machine's capacity, features, and production output. Their machines are available in different models, each with its own set of capabilities and specifications. Customers have the option to choose the machine that best suits their specific needs and budget, ensuring that they get the best value for their investment.In addition to their competitive pricing, {} also offers excellent customer service and after-sales support. Their team of experts is readily available to provide guidance and assistance to customers, ensuring that they get the most out of their machines. From installation and training to maintenance and repairs, {} is committed to providing comprehensive support to their customers, making the investment in their interlocking bricks machines even more worthwhile.With a focus on innovation and quality, {} continues to push the boundaries of interlocking bricks machine technology. They are constantly researching and developing new features and improvements to make their machines more efficient, reliable, and user-friendly. This commitment to innovation has earned them a strong reputation in the industry and has solidified their position as a leading manufacturer of interlocking bricks machines.In conclusion, the interlocking bricks machine price from {} is competitive and offers excellent value for money. With a range of high-quality machines to choose from, customers can find the perfect solution for their interlocking bricks production needs. Along with their dedication to customer service and ongoing innovation, {} is well-positioned to meet the growing demand for interlocking bricks machines in the construction industry. Whether it's for large-scale construction projects or smaller-scale ventures, {} has the expertise and resources to support customers in their interlocking bricks production endeavors.

Top Ecological Brick Machines for Sustainable Construction

Introducing the Future of Sustainable Construction with Ecological Brick MachineWith the increasing focus on sustainability and environmental conservation, the construction industry is also embracing innovative solutions to reduce its ecological impact. One such solution is the Ecological Brick Machine, a revolutionary technology that is changing the way bricks are manufactured.The Ecological Brick Machine is a cutting-edge piece of equipment that is designed to produce bricks in an environmentally friendly and sustainable manner. It utilizes an innovative process that minimizes the use of natural resources and reduces the carbon footprint associated with traditional brick manufacturing.The company behind this groundbreaking technology has been a pioneer in the field of sustainable construction for over a decade. They have always been committed to developing products and technologies that prioritize environmental conservation and social responsibility.The Ecological Brick Machine is a testament to their dedication to sustainable practices. By using recycled materials such as fly ash, slag, and other industrial waste, the machine is able to produce high-quality bricks without depleting natural resources or contributing to pollution.In addition to its environmentally friendly production process, the Ecological Brick Machine also offers several advantages over traditional brick manufacturing. It is highly efficient, with the ability to produce a large number of bricks in a short amount of time. This not only reduces production costs but also increases the availability of sustainable building materials in the market.Furthermore, the bricks produced by the Ecological Brick Machine are of superior quality, ensuring strong and durable construction. They have been tested and certified to meet all industry standards, making them a reliable choice for architects and builders.The company’s commitment to sustainability extends beyond the production of the Ecological Brick Machine. They have also implemented responsible practices in their supply chain and operations, ensuring that their entire business is aligned with the principles of environmental conservation.With the increasing demand for sustainable construction materials, the Ecological Brick Machine has garnered significant attention from developers, contractors, and government agencies. Its ability to reduce the ecological impact of construction while providing high-quality building materials makes it an invaluable asset in the industry.By investing in the Ecological Brick Machine, companies can not only contribute to environmental conservation but also differentiate themselves as leaders in sustainable construction. Its innovative technology and proven performance make it a game-changer in the quest for eco-friendly building materials.In conclusion, the Ecological Brick Machine is a prime example of how innovation and sustainability can go hand in hand. With its environmentally friendly production process, high-quality output, and positive impact on the construction industry, it is poised to shape the future of sustainable building materials. The company behind this technology continues to lead the way in promoting responsible and eco-friendly practices in construction, setting a new standard for the industry as a whole.

Revolutionary Brick Making Machine Changing the Construction Industry

Innovative Ash Bricks Making Machine Revolutionizes Construction IndustryThe construction industry is experiencing a paradigm shift with the introduction of the cutting-edge Ash Bricks Making Machine (ABMM). This revolutionary technology, developed by a leading machinery manufacturer, is set to transform the way bricks are produced and used in construction projects around the world.The ABMM is a state-of-the-art machine that is specifically designed to utilize ash, a byproduct of coal combustion, in the production of high-quality bricks. This innovative approach not only addresses the issue of environmental sustainability by reducing the amount of ash waste, but also offers a cost-effective and efficient solution for brick production.With the rapid urbanization and growth of infrastructure projects globally, there has been an increasing demand for sustainable building materials that are both affordable and eco-friendly. The ABMM is set to meet this demand by providing a sustainable alternative to traditional clay bricks, which are not only environmentally damaging to produce but also contribute to the depletion of fertile topsoil.The company behind the development of ABMM has a longstanding reputation for producing high-quality machinery for the construction industry. With a commitment to innovation and sustainability, the company has invested significant resources into research and development to bring this groundbreaking technology to the market.The ABMM is equipped with advanced features that ensure the production of bricks with consistent quality and strength. Its automated process reduces the need for manual labor, thereby increasing productivity and efficiency in brick manufacturing. In addition, the machine is designed to be user-friendly, making it accessible to a wide range of users, from small-scale enterprises to large construction companies.One of the key advantages of the ABMM is its ability to utilize ash as a primary raw material in brick production. This not only reduces the environmental impact of ash disposal but also offers significant cost savings compared to traditional brick production methods. By transforming a waste product into a valuable resource, the ABMM contributes to the circular economy by closing the loop on material utilization.The application of the ABMM extends beyond its environmental and economic benefits. The bricks produced by the machine offer superior thermal and acoustic insulation properties, making them an ideal choice for sustainable building projects. Furthermore, the use of ash in brick production reduces the dependency on traditional clay deposits, which are finite and non-renewable resources.Innovation is at the core of the company's philosophy, and the development of the ABMM is a testament to its commitment to driving positive change in the construction industry. The machine has undergone rigorous testing and optimization to ensure its reliability and performance, and it has already garnered significant interest from construction professionals and developers alike.As the construction industry continues to evolve, the demand for sustainable and cost-effective building materials is set to grow. The introduction of the ABMM represents a significant step forward in meeting this demand, offering a viable solution for the production of eco-friendly bricks that meet the highest standards of quality and durability.With the ABMM, the company aims to empower construction professionals with a game-changing technology that not only enhances their productivity and efficiency but also aligns with their sustainability goals. As the industry embraces the shift towards sustainable construction practices, the ABMM is poised to play a pivotal role in shaping the future of brick production and building materials.In conclusion, the Ash Bricks Making Machine (ABMM) represents a groundbreaking development in the construction industry, offering a sustainable and cost-effective solution for brick production. With its innovative approach to utilizing ash as a raw material, the ABMM is poised to revolutionize the way bricks are produced and used in construction projects. The company's commitment to innovation and sustainability has resulted in the creation of a game-changing technology that has the potential to drive positive change in the industry.

Efficient Small Cement Block Making Machine for Your Business

Small Cement Block Making Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has seen a significant shift towards more sustainable and efficient building practices. One notable advancement in this area is the development of small cement block making machines, which have revolutionized the way concrete blocks are produced on construction sites.The small cement block making machine, developed by {company}, is a compact and portable device that allows construction workers to produce high-quality cement blocks directly at the construction site. This innovation has not only streamlined the construction process but also reduced the environmental impact of traditional block production methods.{Company} is a leading manufacturer of construction equipment, with a strong focus on sustainability and innovation. The development of the small cement block making machine is a testament to the company's commitment to providing solutions that meet the evolving needs of the construction industry.The small cement block making machine is designed to be user-friendly and highly efficient. It can be operated by a single person and is capable of producing a large number of cement blocks in a relatively short amount of time. This means that construction projects can now produce their own cement blocks on-site, eliminating the need for transporting pre-made blocks from off-site locations.Furthermore, the small cement block making machine is designed to minimize waste and maximize the use of materials. The machine is equipped with advanced technology that allows for precise measurements and consistent block quality, resulting in minimal material wastage. This not only reduces construction costs but also contributes to a more sustainable building process.The introduction of small cement block making machines has also had a significant impact on the environmental footprint of the construction industry. Traditional methods of producing cement blocks involve the use of large-scale machinery and transportation, which can result in high carbon emissions. By bringing the block production process to the construction site, the small cement block making machine reduces the need for transportation and minimizes the environmental impact associated with traditional block production methods.In addition to its environmental benefits, the small cement block making machine also offers economic advantages for construction companies. By producing their own cement blocks on-site, construction projects can significantly reduce their reliance on external suppliers, ultimately saving time and costs associated with transportation and logistics.The small cement block making machine has already been widely adopted by construction companies around the world, with positive feedback on its efficiency and reliability. Its compact design and ease of use make it a versatile tool for a wide range of construction projects, from small-scale developments to large infrastructure projects.Furthermore, {company} continues to invest in research and development to further enhance the capabilities of the small cement block making machine. The company is committed to exploring new technologies and materials that can be integrated into the machine, with the goal of continually improving its performance and environmental impact.As the construction industry continues to evolve and prioritize sustainability, the small cement block making machine is expected to play a significant role in the future of construction. Its ability to streamline the block production process, reduce waste, and lower carbon emissions make it a valuable tool for modern construction projects.In conclusion, the small cement block making machine developed by {company} has brought about a significant change in the way cement blocks are produced in the construction industry. Its compact design, efficiency, and sustainability benefits make it a valuable asset for construction projects around the world. With ongoing advancements and innovation, this machine is set to further transform the construction industry and contribute to more sustainable and efficient building practices.

High-Quality and Efficient Mud Brick Making Machine for Sale

The Clay Mud Brick Making Machine is a revolutionary product that is set to transform the way bricks are made. This innovative machine, produced by a leading manufacturing company, promises to streamline the process of brick-making and make it more efficient and cost-effective.With the increasing demand for bricks in the construction industry, there is a need for more advanced and efficient methods of production. The Clay Mud Brick Making Machine is designed to meet this demand by providing a solution that is both practical and sustainable.The machine is capable of producing high-quality bricks using clay and mud, which are readily available and inexpensive materials. This makes it an ideal option for businesses looking to reduce their production costs and increase their profitability.In addition to its cost-saving benefits, the Clay Mud Brick Making Machine is also environmentally friendly. By using natural materials such as clay and mud, it minimizes the need for synthetic materials and reduces the carbon footprint of the brick-making process.Furthermore, the machine is easy to operate and requires minimal training, making it suitable for both large-scale production facilities and small-scale businesses. Its user-friendly design ensures that operators can quickly learn how to use the machine and start producing bricks with ease.The company behind the Clay Mud Brick Making Machine has a solid reputation for producing high-quality industrial equipment. With years of experience in the manufacturing industry, they have a deep understanding of the needs and challenges faced by businesses in various sectors.Their commitment to innovation and excellence is evident in the design and functionality of the Clay Mud Brick Making Machine. The company's dedication to quality and customer satisfaction sets them apart from their competitors and makes them a trusted name in the industry.The Clay Mud Brick Making Machine is just one example of the company's innovative approach to manufacturing. They continuously strive to develop new and improved solutions that address the evolving needs of the market and help businesses stay competitive in a rapidly changing environment.As the demand for sustainable and cost-effective building materials continues to grow, the Clay Mud Brick Making Machine is well-positioned to become a game-changer in the construction industry. Its ability to produce high-quality bricks using natural materials, coupled with its user-friendly design and environmental benefits, makes it a valuable asset for businesses looking to enhance their production capabilities.In conclusion, the Clay Mud Brick Making Machine has the potential to revolutionize the way bricks are made. Its cost-saving benefits, environmental advantages, and user-friendly design make it a valuable asset for businesses in the construction industry. With the backing of a reputable manufacturing company, this innovative machine is set to become a game-changer in the market and pave the way for a more sustainable and efficient approach to brick-making.

Compact Brick Making Machine: A Revolutionary Solution for Efficient Brick Production

Miniature brick making machines are becoming increasingly popular, thanks to their ability to deliver quality bricks at an affordable cost. These machines are compact and efficient, and they are perfect for use by both commercial and home users. With their small size, they can be easily placed in a garage or small workshop.One such brick making machine, which is disrupting the market is the Mini Brick Making Machine, produced by a company with a unique vision and mission. The {company name removed} manufacture this innovative product, which is designed to deliver premium performance and exceptional output.{Company name removed} has been in the manufacturing industry for many years. Their expertise lies in the production of brick making machines, which have been designed to meet the demands of the modern world. They have worked tirelessly to perfect their craft, and the Mini Brick Making Machine is a testament to their commitment and dedication.The Mini Brick Making Machine is a revolutionary brick making machine that has captured the hearts of builders and DIY enthusiasts alike. Its small size makes it perfect for use in small to medium-sized projects, yet it has the ability to produce high-quality bricks in large quantities.The machine is designed with a sleek and modern aesthetic that will make it stand out in any workspace. The compact design of the Mini Brick Making Machine ensures that it is easily portable and can be used in remote areas with ease. It is also available in different colors so that customers can choose the one that best suits their preferences.The machine boasts of a high-tech control panel that allows users to operate it with ease. The panel provides detailed instructions on how to use the machine, making it easy for even beginners to get started. The control panel also enables users to monitor the production process, ensuring that they can make adjustments as needed to improve output.The Mini Brick Making Machine features a unique mold box that comes in different shapes and sizes. This feature allows users to produce a wide range of bricks, depending on their specific needs. Whether it is paving bricks, perforated bricks or solid bricks, the mold box can be easily changed to produce the desired shape.One of the most significant advantages of the Mini Brick Making Machine is its automatic operation feature. This feature saves time, reduces labor costs, and ensures that the output is consistent. The machine can automatically mix the material, compress the mixture, and then deliver the finished product, without the need for human intervention. This function makes it perfect for use in large projects that require high-quality bricks produced in bulk.The Mini Brick Making Machine also has a high-quality motor that delivers exceptional power while remaining efficient. The motor is designed to provide a smooth and consistent operation, ensuring that the machine can handle large workloads without breaking down. This feature gives users the confidence they need to tackle any project, no matter how big or small.{Company name removed} has gone to great lengths to ensure that their Mini Brick Making Machine is environmentally friendly. The machine has a low carbon footprint and produces minimal waste. This makes it an eco-friendly option for those who care about the environment.The Mini Brick Making Machine is also easy to maintain and upkeep. Its simple design ensures that there are minimal moving parts, which translates to fewer breakdowns and less wear and tear. This feature makes it a cost-effective option for those looking to save money on maintenance costs.In conclusion, the Mini Brick Making Machine is a game-changer in the brick making industry. Its innovative design, automatic operation, and eco-friendly features make it a must-have for builders and DIY enthusiasts alike. With its ability to produce high-quality bricks at an affordable cost, it is an investment worth making. {Company name removed} has created a masterpiece that will undoubtedly transform the building industry for years to come.