Revolutionizing Brick Making with Advanced Machine Technology

By:Admin

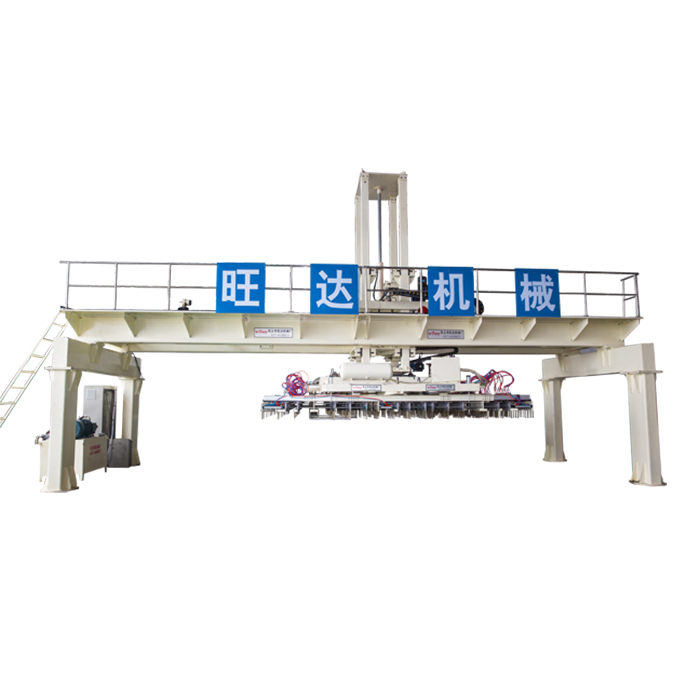

The new brick making machine, developed by {}., is a fully automated and highly advanced piece of equipment that has the capability to produce a wide range of brick products with high precision and quality. This cutting-edge technology has caught the attention of the brick manufacturing industry and is set to reshape the way bricks are produced on a global scale.

With the increasing demand for sustainable and eco-friendly building materials, the new brick making machine is a game-changer. It is designed to optimize the use of raw materials and reduce waste, making it an environmentally responsible choice for brick production.

{}., the company behind this ground-breaking innovation, has been a leader in the construction machinery industry for over two decades. The company is known for its commitment to research and development, constantly striving to create innovative solutions that meet the evolving needs of the construction sector.

The new brick making machine is the result of extensive research and development carried out by {}.'s team of engineers and experts. It incorporates the latest technology and design principles to deliver a machine that is not only efficient and productive but also easy to operate and maintain.

One of the key features of the new brick making machine is its versatility. It has the capability to produce a wide range of brick products, including standard bricks, interlocking bricks, and pavers, allowing manufacturers to diversify their product offerings and meet the varied demands of the market.

Furthermore, the machine is equipped with advanced automation features, reducing the need for manual labor and streamlining the production process. This not only increases efficiency but also ensures consistent quality and precision in every brick produced.

In addition to its innovative design and advanced technology, the new brick making machine also prioritizes sustainability. It is designed to minimize energy consumption and reduce carbon emissions, aligning with the global shift towards eco-friendly manufacturing practices.

The introduction of this new brick making machine is expected to have a significant impact on the brick manufacturing industry. It will enable manufacturers to enhance their productivity, reduce production costs, and improve the overall quality of their brick products. Additionally, its sustainable design will appeal to environmentally conscious consumers and builders, further driving its adoption in the market.

As the construction industry continues to evolve, innovative solutions like the new brick making machine by {} will play a crucial role in shaping the future of brick production. With its advanced technology, versatility, and focus on sustainability, this machine is set to become the go-to choice for brick manufacturers worldwide, cementing {}'s position as a leader in the industry.

In conclusion, the introduction of the new brick making machine by {} represents a significant milestone in the evolution of brick manufacturing. Its innovative design, advanced technology, and focus on sustainability make it a game-changer for the industry, offering manufacturers a cost-effective, efficient, and environmentally responsible solution for brick production. This ground-breaking innovation is a testament to {}.'s commitment to pushing the boundaries of construction machinery and delivering cutting-edge solutions that drive progress and sustainability in the industry.

Company News & Blog

Top Bricks and Blocks Machinery for Quality Construction

Title: Revolutionary Machinery Set to Transform the Construction IndustryIntroductionIn a groundbreaking development set to revolutionize the construction industry, a leading machinery manufacturing company is set to unveil its latest innovation. Bricks and Blocks Machinery, a pioneering force in the sector, has unveiled a cutting-edge solution that promises to streamline construction processes, enhance efficiency, and address global sustainability concerns.The Bricks and Blocks Machinery SolutionBricks and Blocks Machinery, a global leader in machinery manufacturing, has announced the development of a state-of-the-art construction system that efficiently produces bricks and blocks of the highest quality. The breakthrough technology aims to disrupt traditional construction practices, ultimately reducing costs and environmental impact, whilst also increasing productivity and site safety.The new machinery, branded here as the "Revolutionary Construction System" (RCS), ensures precision and consistency in block and brick production. By leveraging the latest advancements in automation, robotics, and engineering, Bricks and Blocks Machinery has combined cutting-edge technology with sustainability. RCS employs alternative construction materials alongside the traditional use of concrete, enabling builders to reduce their carbon footprint and promote eco-friendly practices.Key Features and Advantages1. Enhanced Efficiency: The Revolutionary Construction System (RCS) eliminates redundancies and optimizes construction processes. RCS can produce a large quantity of blocks and bricks in a fraction of the time required by traditional methods, thanks to its automation capabilities. This increased efficiency leads to faster project completion and greater customer satisfaction.2. Improved Quality: Through its precision-engineered design and advanced technology, the RCS ensures consistent quality and uniformity in block and brick production. By minimizing human error, RCS leads to superior building materials that are more capable of withstanding adverse environments and facilitating durable construction.3. Sustainable Practices: Bricks and Blocks Machinery addresses environmental concerns by offering an alternative to conventional construction materials. The RCS expands the usage of eco-friendly materials in brick and block production, reducing the industry's reliance on traditional concrete and decreasing the overall carbon footprint of construction projects.4. Safety Considerations: The RCS automates various stages of construction, minimizing the involvement of human labor in risky tasks and reducing the potential for accidents. This revolutionary system prioritizes safety, ensuring the well-being of workers while delivering the highest quality output.Implications for the Construction IndustryThis innovative construction system by Bricks and Blocks Machinery has the potential to transform the industry on multiple fronts. By accelerating the construction process, reducing costs, and promoting sustainable practices, the RCS enables companies to execute projects on time and within budget. Additionally, this cutting-edge solution aligns with the shifting demands of the modern world, as more emphasis is placed on sustainable development and green construction practices.The combination of enhanced efficiency and superior quality offered by RCS is likely to attract industry leaders, prompting widespread adoption of this revolutionary machinery. As construction companies embrace this technology, they gain a competitive advantage, as they can complete projects not only faster but also in a more sustainable manner, meeting evolving environmental regulations and customer demands simultaneously.ConclusionBricks and Blocks Machinery's Revolutionary Construction System (RCS) is set to disrupt the global construction industry. By combining technological advancements with sustainable practices, this innovative machinery enhances efficiency, improves quality, reduces environmental impact, and prioritizes worker safety. The RCS marks a significant leap forward, representing a paradigm shift in the construction sector. As Bricks and Blocks Machinery revolutionizes the way we build, it paves the way towards a more sustainable and efficient future for construction.

Unlocking the Potential: Discover the Process of Creating Interlocking Bricks

Title: Revolutionizing Construction: Sustainable, Versatile Interlocking BricksIntroduction:In an era where the need for sustainable construction materials is rapidly growing, an innovative company is stepping up to provide a forward-thinking solution. With a commitment to environmental friendliness and versatility, {Company Name}'s ingenious interlocking bricks are poised to revolutionize the construction industry, offering builders and architects a sustainable alternative to traditional bricks.Sustainable Construction Practices: An Urgent NeedWith growing awareness of the environmental impact of traditional construction materials and practices, the need for more sustainable alternatives has never been greater. The widespread use of conventional bricks leads to deforestation, excessive energy consumption, and waste production. In this context, {Company Name} emerges as a trailblazer, paving the way for a more sustainable future in the construction sector.Innovative Interlocking Bricks: Key Features and Advantages{Company Name}'s interlocking bricks redefine the concept of construction materials. Made from a blend of locally sourced and recycled materials, these bricks offer numerous benefits, making them an ideal choice for builders and architects alike. Key features of {Company Name}'s interlocking bricks include:1. Environmentally Friendly: By utilizing recycled materials, {Company Name} reduces environmental impact, minimizing the need for new resources. This eco-conscious approach ensures sustainable construction practices without compromising quality or safety.2. Efficient Construction: The interlocking design of these bricks eliminates the need for mortar, significantly speeding up the construction process. This innovative feature allows projects to be completed in considerably less time, reducing labor costs and increasing efficiency.3. Structural Integrity: The interlocking system creates a strong bond between the bricks, resulting in a robust and durable structure. This design ensures structural integrity, making the buildings constructed with {Company Name}'s interlocking bricks resistant to seismic activities and other potential hazards.4. Versatility of Design: The interlocking bricks' modular construction provides endless design possibilities, enabling builders and architects to bring their creative visions to life. These bricks can be used for various applications, including residential buildings, schools, and even commercial complexes, catering to a wide range of construction needs.5. Cost-Effective: In addition to being environmentally friendly and versatile, {Company Name}'s interlocking bricks offer cost-effective solutions for construction projects. By using locally sourced materials and removing the need for mortar, these bricks reduce material and labor costs, making sustainable construction accessible to a larger market.{Company Name}: Revolutionizing the Construction IndustryFounded with the mission to transform the construction sector, {Company Name} has emerged as a leader in sustainable construction practices. Their commitment to eco-consciousness, innovation, and affordability sets them apart from traditional brick manufacturers. By championing the use of interlocking bricks, {Company Name} is not only providing a sustainable solution but also empowering builders and architects to create modern, resilient structures.Environmental Impact and Future SustainabilityBy replacing conventional bricks with {Company Name}'s interlocking bricks, the construction industry can significantly reduce deforestation, carbon emissions, and waste generation. The long-lasting durability of these bricks also minimizes the need for expensive maintenance and repairs.Furthermore, {Company Name} aims to continuously improve its production processes, exploring ways to incorporate even more sustainable practices. From implementing renewable energy sources in manufacturing to optimizing raw material usage and recycling, the company strives to minimize its environmental footprint continuously.Conclusion:With their commitment to sustainability, innovation, and affordability, {Company Name} is spearheading a revolution in the construction industry. By offering builders and architects a versatile, eco-friendly alternative, their interlocking bricks are setting new standards for sustainable construction practices. As the demand for environmentally conscious construction materials continues to rise, {Company Name} is well-positioned to lead the way towards a more sustainable future.

How to Find the Best Brick Machine Making Services for Your Needs

Brick Machine Making Company Innovates with Sustainable Manufacturing PracticesIn the world of manufacturing, sustainability has become an increasingly important consideration. With the global focus on environmental conservation and the need for reduction of carbon emissions, companies are constantly seeking innovative ways to produce goods in an eco-friendly manner. And one company that has emerged as a leader in this regard is {Company Name}, a renowned brick machine making company.{Company Name} has been at the forefront of developing cutting-edge brick making machines that are not only efficient and reliable but also sustainable. The company's commitment to environmental responsibility is evident in its production processes, which are designed to minimize waste and energy consumption while maximizing the use of recycled materials.One of the key innovations that {Company Name} has introduced is the use of advanced technology to optimize the production of bricks. The company's brick making machines are equipped with state-of-the-art features that ensure the efficient use of raw materials, resulting in minimal waste generation. Additionally, the machines are designed to operate with high energy efficiency, reducing the overall carbon footprint of the production process.Furthermore, {Company Name} has integrated the use of recycled materials into its brick making process. By utilizing recycled aggregates and waste materials, the company not only reduces its reliance on natural resources but also contributes to the reduction of waste in landfills. This circular approach to manufacturing aligns with the principles of a circular economy and reflects {Company Name}'s dedication to sustainable practices.In addition to its focus on sustainable manufacturing, {Company Name} also places a strong emphasis on product quality and innovation. The company's team of engineers and designers continually strives to develop new and improved brick making machines that set industry standards for performance and reliability. With a commitment to delivering high-quality products, {Company Name} has established itself as a trusted partner for businesses in the construction industry.{Company Name}'s dedication to sustainability and innovation extends beyond its manufacturing processes. The company also prioritizes the well-being of its employees and the communities in which it operates. By adhering to strict safety standards and promoting a culture of environmental responsibility, {Company Name} ensures that its operations have a positive impact on both people and the planet.As a testament to its leadership in sustainable manufacturing, {Company Name} has received several accolades and certifications for its commitment to environmental stewardship. The company's efforts have been recognized by industry organizations and regulatory bodies, further solidifying its position as a responsible corporate citizen.Looking ahead, {Company Name} remains committed to pushing the boundaries of sustainable manufacturing and contributing to a greener future. The company continues to invest in research and development to further enhance the efficiency and sustainability of its brick making machines. By leveraging the latest advancements in technology and sustainable practices, {Company Name} is poised to remain a driving force in the evolution of the manufacturing industry.In conclusion, {Company Name} stands as a shining example of a company that is dedicated to sustainable manufacturing practices. With its focus on efficiency, recycling, and innovation, the company has set a new standard for environmentally responsible production processes. As the demand for sustainable solutions continues to grow, {Company Name} is well-positioned to lead the way towards a more sustainable and prosperous future for the manufacturing industry.

Create your own clay hollow making machine line at home with this easy-to-use machine

The renowned company, with a long-standing history in the manufacturing industry, has recently launched a state-of-the-art Clay Hollow Making Machine Line. This cutting-edge product has been developed to meet the ever-growing demand for efficient and high-quality machinery in the construction and manufacturing sectors.The Clay Hollow Making Machine Line is designed to streamline the process of producing hollow clay bricks, which are widely used in construction for their durability and strength. The machine line incorporates innovative technology and advanced engineering, ensuring a high level of precision and efficiency in the manufacturing process.One of the key features of the Clay Hollow Making Machine Line is its capability to produce a large volume of hollow clay bricks in a relatively short period of time. This is made possible by the integration of automated systems and intelligent controls, which optimize the production process and minimize human intervention.Moreover, the machine line is equipped with a range of customization options, allowing for the production of hollow clay bricks in various shapes and sizes to meet specific project requirements. This flexibility makes the machine line highly versatile and adaptable to a wide range of construction applications.In addition to its advanced capabilities, the Clay Hollow Making Machine Line is also designed with a focus on sustainability and environmental responsibility. The machine line incorporates energy-efficient systems and is designed to minimize waste and emissions during the production process, aligning with the company's commitment to sustainable manufacturing practices.The company's dedication to quality and reliability is evident in the rigorous testing and quality control measures that are applied to the Clay Hollow Making Machine Line. Each machine undergoes extensive testing to ensure that it meets the highest standards of performance and durability, providing customers with a product that is built to last.The launch of the Clay Hollow Making Machine Line represents a significant milestone for the company, further solidifying its position as a leader in the manufacturing industry. With a strong focus on innovation and customer satisfaction, the company continues to strive for excellence in its product offerings, setting new benchmarks for quality and efficiency in the industry.In conjunction with the launch of the Clay Hollow Making Machine Line, the company has also expanded its support and service offerings to ensure that customers receive the highest level of assistance and expertise. A dedicated team of specialists is available to provide guidance on the installation, operation, and maintenance of the machine line, as well as to offer technical support and troubleshooting assistance as needed.The introduction of the Clay Hollow Making Machine Line underscores the company's commitment to driving progress and innovation in the manufacturing sector. By leveraging its extensive expertise and experience, the company has developed a product that is poised to revolutionize the production of hollow clay bricks, offering a solution that is highly efficient, reliable, and environmentally sustainable.Looking ahead, the company remains focused on further advancing its product capabilities and expanding its offerings to meet the evolving needs of the construction and manufacturing industries. With a strong foundation built on a legacy of excellence, the company is well-positioned to continue leading the way in delivering cutting-edge solutions for the global market.

Innovative Brick Extruder Technology: An Overview

Brick Extruder Revolutionizes Construction IndustryThe construction industry has seen a major shift in recent years with the introduction of innovative technologies that have streamlined the building process. One such technology that has been making waves in the industry is the Brick Extruder, a state-of-the-art machine that has the ability to revolutionize the way bricks are produced and used in construction.The Brick Extruder, developed by a leading construction equipment manufacturer, is a cutting-edge machine that is changing the way bricks are manufactured. Traditional brick-making processes involve a labor-intensive and time-consuming method of mixing the raw materials, compressing the mixture, and then baking the bricks in a kiln. This method not only requires a large amount of energy and resources but also takes a significant amount of time to produce the final product.The Brick Extruder, on the other hand, automates the entire process, making it faster, more efficient, and environmentally friendly. The machine is capable of mixing the raw materials, shaping the bricks, and extruding them in a continuous process, significantly reducing the time and resources required for brick production. Additionally, the Brick Extruder is designed to produce bricks of uniform size and shape, ensuring high-quality and consistent building materials for construction projects.One of the key features of the Brick Extruder is its versatility. The machine is capable of producing a wide range of brick types, including solid bricks, hollow bricks, perforated bricks, and even special-shaped bricks, giving construction companies the flexibility to meet various project requirements. This adaptability makes the Brick Extruder an ideal solution for both small-scale and large-scale construction projects, providing companies with the ability to produce custom bricks for a variety of building applications.In addition to its operational efficiency, the Brick Extruder also boasts environmental benefits. The machine is designed to reduce waste and optimize the use of raw materials, resulting in minimal environmental impact. By streamlining the brick-making process and minimizing the reliance on traditional kiln firing, the Brick Extruder helps to conserve energy and lower carbon emissions, making it an eco-friendly option for sustainable construction practices.Furthermore, the Brick Extruder is equipped with advanced technology and automation features that improve productivity and reduce labor costs. The machine's user-friendly interface and automated controls make it easy to operate, requiring minimal manual intervention and supervision. This not only increases production efficiency but also reduces the need for skilled labor, making the Brick Extruder a cost-effective solution for construction companies.The introduction of the Brick Extruder marks a significant advancement in the construction industry, offering a modern and efficient approach to brick manufacturing. With its ability to streamline the production process, provide high-quality bricks, and reduce environmental impact, the Brick Extruder is poised to revolutionize the way construction materials are manufactured and utilized.As construction companies continue to seek innovative solutions to improve their operations and meet the demands of modern building projects, the Brick Extruder stands out as a game-changing technology that is reshaping the industry. With its potential to drive efficiency, sustainability, and cost-effectiveness, the Brick Extruder is set to make a lasting impact on the future of construction.

Efficient Clay Mixing Machine Enhances Brick Production - Stay Informed with Latest News

Brick Clay Mixing Machine: Revolutionizing the Construction Industry The construction industry has seen significant changes over the past few decades. With technological advancements and innovative machines, construction companies can build structures faster, cheaper, and more efficiently. One of the most critical machines utilized in the construction industry is the brick clay mixing machine. A brick clay mixing machine is a high-performance device used to mix and break up clay or other materials to produce high-quality bricks. These machines feature heavy-duty motors and other advanced elements that ensure an efficient and reliable workflow. Brick clay mixing machines are used in the production of various brick types, including concrete blocks, hollow bricks, perforated bricks, interlocking bricks, and much more.A leading manufacturer of brick clay mixing machines is based in China. With over two decades of experience in the construction industry, the company has emerged as a leading player in the market. They have a reputation for delivering high-quality, efficient, and reliable machines that help their clients achieve their construction goals.The brick clay mixing machines designed by this company are designed to meet the growing needs of clients in the construction industry. Their machines are known for their user-friendliness and dependability. The mixing machines come in various sizes and capacities to meet the specific need and budget of each client. The company has a team of experienced engineers who utilize advanced technology to design the machines. The engineers pay attention to details, ensuring the machines are eco-friendly, low-maintenance, easy to operate, and efficient. The machines are also designed to operate on minimal electricity, reducing the overall energy costs for the clients.In addition to the advanced features, the company also guarantees quality service. They provide training to the clients on how to operate and maintain the machines. The customer service team is also available round the clock to address any issues that may arise during the use of the machines. The company's dedication to excellent customer service ensures that their clients have a stress-free experience when using their brick clay mixing machines.The brick clay mixing machines by this company have numerous benefits to the construction industry. Firstly, they eliminate the manual labor required in mixing the clay, ultimately reducing labor costs. Secondly, these machines increase the quality of the bricks produced, ensuring that construction projects have better durability and longevity. Thirdly, the brick clay mixing machines help construction companies meet deadlines, leading to increased productivity and higher profits.One of the clients that have benefitted from the brick clay mixing machine is XYZ Construction Company. Founded in 1999, XYZ Construction Company has been providing top-notch construction services to its clients for over two decades. They have executed numerous projects ranging from residential to commercial buildings. Before XYZ Construction Company started using brick clay mixing machines from the China-based company, their brick production process was slow and labor-intensive. The manual mixing of clay took hours, leading to project delays. With the introduction of the brick clay mixing machines, the production process was more efficient and faster. The machines ensured consistent quality, increased brick production, and fewer delays. As a result, XYZ Construction Company was able to take on more projects and deliver them within the set timelines, leading to an increase in profits over time.In summary, brick clay mixing machines are revolutionizing the construction industry, and China remains at the forefront of designing high-quality machines. With its advanced features, quality service, and eco-friendliness, the brick clay mixing machine by the Chinese manufacturer has transformed the brick production process, making it faster, more efficient, and with better quality results. Companies that use these machines have seen an increase in productivity, profitability, and customer satisfaction.

Top Quality Brick Machine Available in India: Find Out More

The brick making industry in India has seen a significant technological advancement with the introduction of advanced brick making machines. These machines have revolutionized the traditional brick making process and are helping to increase efficiency and productivity in the brick manufacturing sector.One of the key players in this industry is a company that has been at the forefront of developing innovative and high-quality brick making machines. With their state-of-the-art technology and commitment to research and development, they have become a trusted name in the brick making machinery market.The company's brick making machines are known for their robust construction, high efficiency, and user-friendly operation. They offer a wide range of machines that cater to the diverse needs of brick manufacturers, including automatic, semi-automatic, and manual machines. Their machines are also designed to produce various types of bricks such as concrete, clay, fly ash, and interlocking bricks.The brick making machines from this company are equipped with advanced features such as automatic material feeding, mold vibrating, and hydraulic pressing, which ensure consistent and high-quality brick production. These machines also have a high production capacity, allowing brick manufacturers to meet the growing demand for bricks in the construction industry.One of the key advantages of using these machines is their energy efficiency and cost-effectiveness. The company has incorporated energy-saving technologies in their machines, which not only reduce the overall operational costs but also contribute to environmental sustainability.Furthermore, the company provides comprehensive after-sales support to its customers, including installation, training, and maintenance services. This ensures that brick manufacturers can maximize the performance and lifespan of their machines, leading to long-term cost savings and operational efficiency.Recently, the company has launched a new range of brick making machines that are specifically tailored to the needs of the Indian market. These machines have been designed to address the challenges faced by brick manufacturers in India, such as the availability of raw materials, labor costs, and environmental regulations.The new range of machines incorporates innovative technologies that help reduce the usage of natural resources, minimize waste generation, and optimize the production process. Additionally, these machines are designed to be more compact and mobile, making them suitable for small-scale brick manufacturing operations in rural areas.The company has also expressed its commitment to supporting the Indian government's initiatives for promoting sustainable and eco-friendly construction practices. They are actively involved in research and development activities to create more advanced and environmentally friendly brick making machines that align with the government's vision for a cleaner and greener India.With the introduction of these advanced brick making machines, the Indian brick manufacturing industry is set to witness a significant transformation. These machines will not only improve the overall productivity and quality of bricks but also contribute to the sustainable development of the construction sector in India.In conclusion, the company's commitment to innovation and sustainability has positioned them as a leading provider of advanced brick making machines in India. Their machines are making a positive impact on the brick manufacturing industry by increasing efficiency, reducing costs, and promoting environmental responsibility. As the demand for high-quality bricks continues to rise in India, these advanced machines are expected to play a critical role in shaping the future of the brick making industry in the country.

Affordable and Efficient Brick Making Machine - Automates the Brick Production Process

In today’s fast-paced world, the need for efficient and cost-effective manufacturing is becoming increasingly important. From small startups to large-scale industrial corporations, businesses are continuously looking to automate their manufacturing processes to save time and reduce labour costs. With this in mind, the Automatic Brick Making Machine is fast becoming a popular solution to meet these needs.The Automatic Brick Making Machine is a high-tech solution specially designed for the manufacturing of bricks in large quantities. This machine uses hydraulic pressure and molds to create bricks from various materials such as clay, sand, cement, and fly ash. The process of manufacturing bricks using an Automatic Brick Making Machine is fast, efficient, and cost-effective.Leading the market in Automatic Brick Making Machines is a company that specializes in the manufacture of high-tech machines for various industries. The company, which shall remain nameless, prides itself in producing quality machines that are innovative, efficient, and user-friendly. With years of experience in the manufacturing sector, the company’s team of engineers and designers have been able to develop an Automatic Brick Making Machine that meets the expectations of their customers.One of the features that sets this Automatic Brick Making Machine apart is its ability to produce up to 20,000 bricks per hour. This allows businesses to produce large quantities of bricks at a fraction of the time and cost of traditional brick-making methods. Furthermore, the machine allows for customization of brick sizes and shapes, enabling businesses to meet specific market demands.Another benefit of the Automatic Brick Making Machine is the minimal labour required. The machine is fully automated, meaning that only a few staff members are required to operate it. This significantly reduces labour costs and allows businesses to free up staff to focus on other areas of the business.The Automatic Brick Making Machine is also environmentally friendly, using up to 90% less water than traditional brick-making methods. This dry process also means that there is no need for kiln firing, which further reduces the machine’s carbon footprint.Other features of the Automatic Brick Making Machine include its easy to operate system, which requires minimal training for staff, and its low maintenance requirements. The machine is built with high-quality materials, ensuring that it is durable and long-lasting.As business owners look for cost-effective solutions to meet their manufacturing needs, the Automatic Brick Making Machine is becoming increasingly popular. With its fast production speed, low labour costs, and environmentally friendly capabilities, it is a viable option for brick manufacturers looking to scale up their operations.In conclusion, the Automatic Brick Making Machine is a perfect solution for brick manufacturers. With its efficient and environmentally friendly features, it offers an efficient and cost-effective way of producing bricks in large quantities. The company behind the machine takes pride in their innovative and high-quality machines, which are designed to meet the needs of the consumers. It is clear that the Automatic Brick Making Machine is a game-changer for the brick manufacturing industry, and businesses that incorporate it into their manufacturing processes will undoubtedly reap the benefits.

Find the best deals on clay brick making machines

The demand for clay brick making machines has seen a significant increase in recent years, as the construction industry continues to thrive globally. As a result, the market for these machines has become increasingly competitive, with a wide range of manufacturers offering various models at different price points.One of the key players in this market is a leading company in the field of manufacturing and supplying clay brick making machines. With a strong reputation for quality and reliability, the company has become a preferred choice for many construction companies and contractors.Recently, the company announced a competitive price for their clay brick making machines, making it even more accessible to a wider range of customers. The company has positioned itself as a cost-effective option for those looking to invest in high-quality brick making equipment.The price of the clay brick making machines offered by the company reflects their commitment to providing value for money. The company understands the importance of offering competitive pricing in today's market, especially as construction companies look to maximize their investments and minimize costs.In addition to the competitive pricing, the company also prides itself on the quality of its machines. Their clay brick making machines are built to last, with a focus on durability and performance. This is in line with the company's mission to provide reliable and efficient equipment that meets the needs of their customers.The company has a wide range of clay brick making machines to choose from, catering to different production capacities and budget requirements. This variety ensures that customers can find the right machine for their specific needs, whether it's for a small-scale project or a large-scale operation.The company's extensive experience in the industry has allowed them to refine their manufacturing processes, resulting in high-quality machines that deliver consistent results. This has earned them a strong reputation among their customers, who continue to trust in the reliability and performance of their equipment.Moreover, the company is known for its excellent customer service and support. Their team of experts is always on hand to provide assistance and guidance to customers, whether it's in selecting the right machine or addressing any technical issues that may arise.Customers can also benefit from the company's comprehensive warranty and after-sales service, ensuring peace of mind and long-term support for their investment in a clay brick making machine.With the competitive pricing and strong reputation for quality and reliability, the company has positioned itself as a leading choice for those in need of clay brick making machines. Their commitment to customer satisfaction and their dedication to providing top-notch equipment make them a preferred partner for construction companies and contractors across the globe.In conclusion, the competitive price offered by the company for their clay brick making machines, combined with their commitment to quality and customer satisfaction, makes them a standout choice in the market. As the demand for these machines continues to grow, the company is well-positioned to meet the needs of customers looking for reliable and cost-effective solutions for their brick making requirements.

Highly Efficient Clay Brick Making Production Line for Sale

In recent years, there has been a growing demand for clay bricks in the construction industry due to their durability and aesthetic appeal. In response to this demand, (Company Name) has introduced a state-of-the-art Clay Brick Making Production Line that is set to revolutionize the brick manufacturing process.With over (number of years) years of experience in the construction industry, (Company Name) has established itself as a leading manufacturer of construction materials. Their commitment to innovation and quality has allowed them to stay ahead of the competition and meet the ever-changing needs of their customers.The new Clay Brick Making Production Line is the latest addition to (Company Name)'s impressive portfolio of products. This production line is equipped with cutting-edge technology and machinery, allowing for the efficient and high-volume production of clay bricks. The line is designed to streamline the manufacturing process, resulting in higher productivity and lower production costs.One of the key features of the Clay Brick Making Production Line is its automation capabilities. With the use of advanced robotics and computerized systems, the production line can operate with minimal human intervention, reducing the risk of errors and increasing overall efficiency. This automation also allows for consistent quality control, ensuring that every clay brick produced meets the highest standards.In addition to its cutting-edge technology, the Clay Brick Making Production Line is also designed with sustainability in mind. (Company Name) has implemented environmentally-friendly practices into the production process, such as using recycled materials and optimizing energy usage. This commitment to sustainability aligns with (Company Name)'s overall mission to minimize its environmental impact and contribute to a more sustainable future.Furthermore, (Company Name) has made significant investments in research and development to ensure that the Clay Brick Making Production Line meets and exceeds industry standards. This dedication to innovation has resulted in a production line that is not only efficient and sustainable but also capable of producing a wide range of clay bricks that cater to different architectural and construction needs.The introduction of the Clay Brick Making Production Line represents (Company Name)'s ongoing commitment to providing its customers with the best-in-class construction materials. By investing in this state-of-the-art production line, (Company Name) aims to not only meet the current demand for clay bricks but also anticipate and cater to future trends in the construction industry.In conclusion, the introduction of (Company Name)'s Clay Brick Making Production Line is set to make a significant impact on the construction industry. With its cutting-edge technology, sustainable practices, and commitment to innovation, this production line is poised to redefine the manufacturing process of clay bricks. As (Company Name) continues to lead the way in the construction materials sector, the Clay Brick Making Production Line stands as a testament to their dedication to excellence and customer satisfaction.