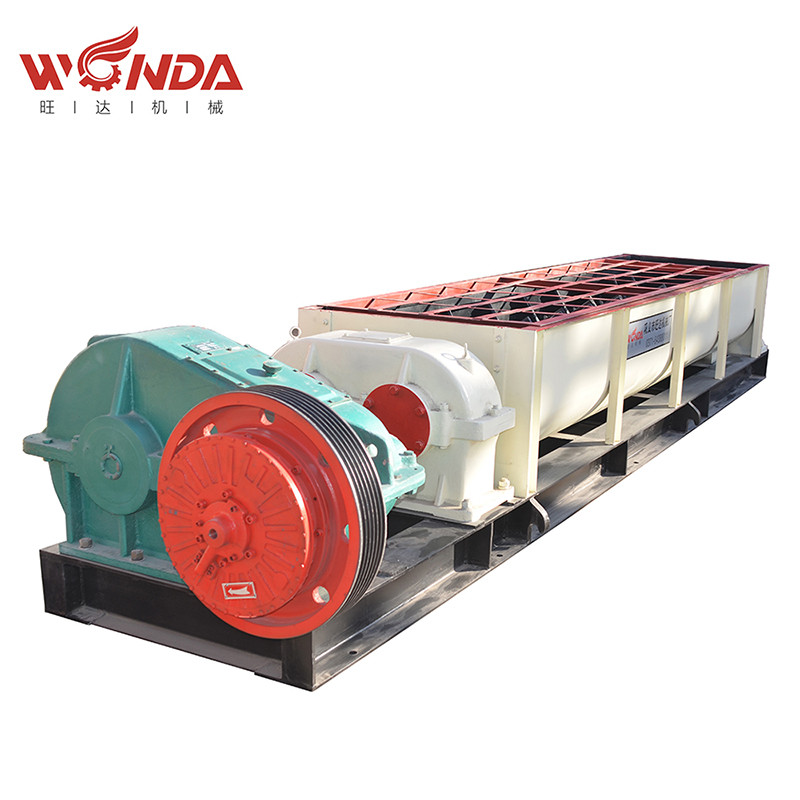

Efficient Clay Soil Brick Making Machine: Revolutionizing the Construction Industry

By:Admin

Introduction:

The construction industry is witnessing a revolutionary change with the introduction of an innovative Clay Soil Brick Making Machine. This advanced technology, developed by a renowned company, marks a significant milestone in brick manufacturing, offering numerous benefits over traditional methods. With the ability to produce high-quality bricks efficiently and sustainably, this new machine has the potential to reshape the way we build.

Body:

1. Overview of the Clay Soil Brick Making Machine:

The Clay Soil Brick Making Machine, designed by a team of industry experts, incorporates cutting-edge technology to streamline the process of brick production. This machine is a result of extensive research and development, focused on creating a solution that reduces manual labor, costs, and environmental impact associated with brick manufacturing.

2. Enhanced Efficiency and Speed:

One of the key advantages of this machine is its superior efficiency compared to traditional methods. By automating key aspects of brick production, such as mixing, pressing, and molding, it significantly reduces the time and effort required. The machine can produce a large number of bricks within a short period, enabling builders to meet project deadlines without compromising on quality.

3. High-Quality Bricks:

The Clay Soil Brick Making Machine ensures consistent and uniform bricks that meet rigorous quality standards. The machine's precisely controlled parameters and automated processes result in bricks with accurate dimensions, smooth surfaces, and excellent structural integrity. These high-quality bricks contribute to the overall strength and aesthetics of the structures they are used in.

4. Versatile Design Options:

This innovative machine offers builders and architects a wide range of design possibilities. It supports customization, allowing for the production of bricks with different shapes, sizes, textures, and colors, thereby enabling creative freedom in construction projects. Whether it's a rustic, traditional look or a modern, sleek design, the machine can cater to various architectural requirements.

5. Sustainable Manufacturing:

Addressing the growing concern for environmental sustainability, the Clay Soil Brick Making Machine promotes eco-friendly manufacturing. It optimizes the use of raw materials, minimizes waste generation, and reduces energy consumption. By utilizing the abundant clay soil resources, it diminishes the need for excessive sand and stone extraction, leading to a greener and more sustainable brick manufacturing process.

6. Cost-Effective Solution:

Aside from its efficiency and eco-friendliness, the Clay Soil Brick Making Machine represents a cost-effective solution for brick manufacturers. Its automated processes and reduced labor requirements translate into lower production costs. Additionally, the machine's durability and long lifespan ensure minimal maintenance and repair expenses, making it an economically viable investment for brick manufacturers.

7. Job Creation:

The introduction of this sophisticated machine not only revolutionizes brick manufacturing but also contributes to job creation. Although some manual labor is still required to operate the machine and oversee the production process, the overall labor demand decreases significantly. This, in turn, allows skilled workers to focus on tasks requiring their expertise, thereby fostering efficiency and productivity.

8. Future Outlook:

The Clay Soil Brick Making Machine sets a new standard for brick manufacturing, promising a future characterized by advanced technology and sustainable practices in the construction industry. With continuous innovations and advancements, the machine holds the potential for further improvements in terms of efficiency, cost-effectiveness, and versatility.

Conclusion:

The Clay Soil Brick Making Machine represents a groundbreaking advancement in brick manufacturing, transforming the industry's standards. Its ability to produce high-quality bricks efficiently, sustainably, and cost-effectively ensures a bright future for the construction sector. With its positive impact on labor demands, environmental sustainability, and design possibilities, this innovative machine stands poised to shape the way we build our cities and structures for years to come.

Company News & Blog

Top Brick Making Machinery Manufacturers: Leading Players in the Market

[Company Introduction]The brick making machinery industry has witnessed significant growth in recent years, and leading manufacturers have played a crucial role in shaping this booming sector. These manufacturers continuously strive to innovate and improve their products to meet the ever-growing demand for quality bricks in various construction projects worldwide. While numerous manufacturers dominate the market, one distinguished company has emerged as a frontrunner, setting new benchmarks for technological advancement and customer satisfaction.[Company Name], a prominent player in the brick making machinery manufacturing industry, has built a strong reputation for producing state-of-the-art equipment that offers outstanding efficiency, durability, and environmentally-friendly features. With a heritage spanning several decades, the company has become synonymous with excellence and reliability, making it the preferred choice for numerous construction firms, contractors, and brick-making enterprises.[Company Name] has always placed customer satisfaction at the core of its business philosophy. By deeply understanding the needs and challenges faced by their clients, the company has successfully developed a wide range of machinery that caters to diverse brick-making requirements.From entry-level semi-automatic machines to fully automated production lines, [Company Name] offers a comprehensive suite of products that ensure high-quality brick manufacturing while minimizing operational costs. The company's manufacturing facilities employ cutting-edge technology and adhere to stringent quality control measures to guarantee superior machinery performance and long-term reliability.Furthermore, [Company Name] consistently invests in research and development to stay ahead of industry trends and technological breakthroughs. By collaborating with leading experts and institutions, the company remains at the forefront of innovation, introducing several groundbreaking features in their machinery.One of the key innovations introduced by [Company Name] is their focus on environmental sustainability. Understanding the importance of reducing the carbon footprint in the construction industry, the company has developed eco-friendly machinery that optimizes energy usage and minimizes waste generation. By adopting these machines, brick manufacturers can contribute to a greener future without compromising on productivity or quality.In addition to its commitment to quality and sustainability, [Company Name] has established a robust network of sales and after-sales support. This network ensures that their customers receive prompt assistance, whether it be technical guidance, spare parts availability, or regular maintenance services. The company's dedicated team of experts works closely with clients to understand their specific requirements and deliver tailored solutions that best suit their needs.Moreover, [Company Name] has successfully expanded its presence internationally, venturing into various markets across the globe. By cultivating partnerships with local distributors and agents, the company has extended its reach, allowing customers worldwide to benefit from their high-quality machinery and exceptional service.As the construction industry continues to flourish, the demand for efficient and reliable brick making machinery is set to surge. With its unwavering commitment to excellence, technological innovation, and customer satisfaction, [Company Name] remains a true leader in the sector, empowering brick manufacturers to build a stronger and more sustainable future through their exceptional machinery.[Conclusion]With its rich heritage, unwavering commitment to quality, and forward-thinking approach, [Company Name] has solidified its position as one of the top brick making machinery manufacturers in the world. As the industry evolves, this leading company continues to redefine the benchmarks of excellence through its cutting-edge technology, eco-friendly solutions, and customer-centric focus.

High-Quality and Efficient Brick Making Equipment: What You Need to Know

As the construction industry continues to grow, the demand for quality building materials is also on the rise. One of the most important components of the industry is brick making equipment. These machines are responsible for producing the clay bricks that are used in construction around the world. And now, with the introduction of a new line of top-quality equipment by one of the leading manufacturers, the industry is set to experience a revolution in efficiency and productivity.{Company Name} has long been known as a top player in the construction industry with a reputation for quality and reliability. The company has built a strong portfolio of tools and equipment that is used by contractors and builders around the world. But now, the company has taken its offerings to a whole new level with the introduction of advanced brick making equipment that is designed to improve the speed and precision of brick production.The new line of equipment is a result of years of research and development, and features the latest advancements in technology. With the ability to produce up to 10,000 bricks per hour, the machines are perfect for large scale commercial construction projects. However, what sets these machines apart is their unparalleled efficiency and precision, which ensures that the bricks produced are of the highest quality and meet the strictest industry standards.The machines are also designed to reduce the amount of waste generated during production. With advanced sensors and automation technology, the equipment can optimize the production process and minimize errors in the brick-making process. This not only saves resources, but also ensures that the bricks produced are of consistent quality.In addition to its advanced production capabilities, the new line of equipment is also designed to be user-friendly and require minimal maintenance. This means that businesses can maximize their productivity and profitability by reducing downtime and minimizing the need for maintenance and repairs. Moreover, the compact design of the equipment means that it can be easily transported and installed at job sites, making it a must-have for construction firms looking for fast and efficient brick production.{Company Name}'s commitment to quality and innovation has made it a trusted name in the construction industry, and the introduction of this new line of equipment is yet another example of its dedication to meeting the evolving needs of the market. With a team of highly skilled engineers and technicians, the company has developed a product that is not only reliable and efficient but also eco-friendly, making it a game-changer in the industry.In conclusion, the introduction of advanced brick making equipment by {Company Name} is set to revolutionize the construction industry. The machines offer unprecedented production capabilities, precision, and efficiency, which will enable builders and construction firms to complete their projects faster and more efficiently. Moreover, the equipment's user-friendly design and low-maintenance requirements will help businesses to maximize their productivity and profitability, making it an essential tool for any construction firm looking to stay ahead of the competition. With this new line of equipment, {Company Name} has once again demonstrated its commitment to quality and innovation, and cemented its position as a key player in the global construction industry.

Compact Brick Making Machine: A Revolutionary Solution for Efficient Brick Production

Miniature brick making machines are becoming increasingly popular, thanks to their ability to deliver quality bricks at an affordable cost. These machines are compact and efficient, and they are perfect for use by both commercial and home users. With their small size, they can be easily placed in a garage or small workshop.One such brick making machine, which is disrupting the market is the Mini Brick Making Machine, produced by a company with a unique vision and mission. The {company name removed} manufacture this innovative product, which is designed to deliver premium performance and exceptional output.{Company name removed} has been in the manufacturing industry for many years. Their expertise lies in the production of brick making machines, which have been designed to meet the demands of the modern world. They have worked tirelessly to perfect their craft, and the Mini Brick Making Machine is a testament to their commitment and dedication.The Mini Brick Making Machine is a revolutionary brick making machine that has captured the hearts of builders and DIY enthusiasts alike. Its small size makes it perfect for use in small to medium-sized projects, yet it has the ability to produce high-quality bricks in large quantities.The machine is designed with a sleek and modern aesthetic that will make it stand out in any workspace. The compact design of the Mini Brick Making Machine ensures that it is easily portable and can be used in remote areas with ease. It is also available in different colors so that customers can choose the one that best suits their preferences.The machine boasts of a high-tech control panel that allows users to operate it with ease. The panel provides detailed instructions on how to use the machine, making it easy for even beginners to get started. The control panel also enables users to monitor the production process, ensuring that they can make adjustments as needed to improve output.The Mini Brick Making Machine features a unique mold box that comes in different shapes and sizes. This feature allows users to produce a wide range of bricks, depending on their specific needs. Whether it is paving bricks, perforated bricks or solid bricks, the mold box can be easily changed to produce the desired shape.One of the most significant advantages of the Mini Brick Making Machine is its automatic operation feature. This feature saves time, reduces labor costs, and ensures that the output is consistent. The machine can automatically mix the material, compress the mixture, and then deliver the finished product, without the need for human intervention. This function makes it perfect for use in large projects that require high-quality bricks produced in bulk.The Mini Brick Making Machine also has a high-quality motor that delivers exceptional power while remaining efficient. The motor is designed to provide a smooth and consistent operation, ensuring that the machine can handle large workloads without breaking down. This feature gives users the confidence they need to tackle any project, no matter how big or small.{Company name removed} has gone to great lengths to ensure that their Mini Brick Making Machine is environmentally friendly. The machine has a low carbon footprint and produces minimal waste. This makes it an eco-friendly option for those who care about the environment.The Mini Brick Making Machine is also easy to maintain and upkeep. Its simple design ensures that there are minimal moving parts, which translates to fewer breakdowns and less wear and tear. This feature makes it a cost-effective option for those looking to save money on maintenance costs.In conclusion, the Mini Brick Making Machine is a game-changer in the brick making industry. Its innovative design, automatic operation, and eco-friendly features make it a must-have for builders and DIY enthusiasts alike. With its ability to produce high-quality bricks at an affordable cost, it is an investment worth making. {Company name removed} has created a masterpiece that will undoubtedly transform the building industry for years to come.

High-Quality Automatic Brick Making Machines for Efficient Construction

Automatic Brick Machine Factory Expands Production Capacity to Meet Growing Demand[City or Country], [Date] - The leading brick machine manufacturing company, formerly known as Automatic Brick Machine Factory, is making strides to further solidify its position as a premier provider of brick manufacturing machinery. With an impressive range of cutting-edge brick machines, the company aims to cater to the rising demand for sustainable and efficient construction solutions around the globe.The Automatic Brick Machine Factory, now rebranded under a new name [Name], has established itself as an industry leader over the years. Guided by their commitment to innovation and customer satisfaction, they have become synonymous with high-quality brick manufacturing machines that adhere to international standards.The introduction of their diverse range of brick machines has revolutionized the construction industry by providing cost-effective and eco-friendly solutions. With a focus on technological advancements, [Name] has consistently delivered state-of-the-art machinery that enables the production of various types of bricks, including interlocking bricks, fly ash bricks, and concrete bricks.Recognizing the increasing demand for sustainable construction practices, [Name] has been proactive in implementing eco-friendly features in their machines. By incorporating intelligent systems that optimize energy consumption and incorporating recycled materials into the production process, the company aims to reduce the carbon footprint associated with brick manufacturing significantly.To accommodate the rapid growth in demand, [Name] has taken measures to expand its production capacity. By implementing advanced manufacturing techniques and investing in cutting-edge machinery, the company aims to increase its output without compromising on the quality of its products. This expansion will allow [Name] to meet the evolving needs of customers while maintaining high levels of customer satisfaction.Furthermore, [Name] prides itself on its exceptional after-sales service, offering comprehensive support to clients worldwide. With an extensive network of service centers and highly skilled technicians, the company ensures that customers can rely on prompt assistance and efficient solutions whenever required.This commitment to customer service has been crucial to [Name]'s success. By prioritizing customer needs and continually striving to exceed expectations, the company has built long-lasting relationships with clients from various industries. Their ability to provide tailored solutions and customized machines for specific requirements has set them apart from competitors in the market.Additionally, [Name] continually emphasizes research and development, investing in new technologies and driving innovation. Through collaboration with engineers and experts in the field, the company continually enhances the performance and efficiency of their brick machines. This commitment to innovation has seen [Name] receive multiple accolades and certifications for excellence in the industry.Considering the global advancements in sustainable construction, [Name] has also expanded its export market, catering to the growing international demand for high-quality brick manufacturing machinery. With a strong presence in countries across [region], the company aims to promote eco-friendly construction practices and contribute to a greener future on a global scale.In conclusion, [Name], formerly Automatic Brick Machine Factory, has emerged as a frontrunner in the brick machine manufacturing industry. With its commitment to innovation, sustainability, and customer satisfaction, the company continues to revolutionize the construction sector through its cutting-edge brick machines. By expanding its production capacities and global market reach, [Name] is poised to play a pivotal role in shaping the future of sustainable construction practices worldwide.

Revolutionizing Brick Manufacturing with the Next Generation of Automated Processes

(News Content)[City], [Date] - In a ground-breaking development in the brick manufacturing industry, an innovative company has introduced an advanced automatic brick manufacturing system. The system, which integrates cutting-edge technology with streamlined production processes, is set to revolutionize the brick production sector.The automatic brick manufacturing system, developed by [Company Name], is poised to address the longstanding challenges faced by traditional brick manufacturing processes. By leveraging state-of-the-art machinery and intelligent automation, the system optimizes the brick production process, enabling cost-efficiency and improved productivity.Unlike traditional brick manufacturing methods that heavily rely on manual labor, [Company Name]'s automatic brick manufacturing system streamlines the entire brick production process. It incorporates robotic systems and advanced machinery to carry out various tasks, such as clay preparation, molding, drying, and firing, with minimal human intervention. This not only reduces the need for a large workforce but also enhances the precision and quality of the finished bricks.Furthermore, the integrated software system plays a crucial role in ensuring seamless coordination and synchronization of all production stages. This intelligent software enables real-time monitoring and control of production parameters, facilitating efficient resource allocation and reducing waste. The system's ability to self-adjust and optimize production parameters based on real-time data further enhances its efficiency.In addition to its ability to streamline production processes, the automatic brick manufacturing system significantly reduces the overall environmental impact associated with traditional brick manufacturing. By implementing advanced energy-saving technologies and employing sustainable practices, [Company Name]'s system promotes eco-friendly brick production. This aligns with the growing global emphasis on sustainability and responsible manufacturing.[Company Name] boasts an impressive track record in the manufacturing industry, having successfully implemented similar innovative systems across various sectors. The company's expertise in automation, coupled with its commitment to quality and efficiency, sets it apart from its competitors. With a team of skilled engineers and technicians, [Company Name] ensures that all its systems are meticulously designed, installed, and maintained to deliver optimal results.The introduction of the automatic brick manufacturing system by [Company Name] is expected to have a profound impact on the brick manufacturing industry. The integration of cutting-edge technology has the potential to streamline operations, increase productivity, and reduce costs for brick manufacturers. Moreover, the system's capability to produce high-quality bricks consistently is set to revolutionize the construction sector, both domestically and internationally.As a result of the system's adoption, brick manufacturers can expect to witness a significant boost in their overall output, enabling them to meet the growing demand for construction materials efficiently. The reduction in labor costs, minimized wastage, and improved product quality further contribute to increased profitability and competitiveness.The automatic brick manufacturing system developed by [Company Name] represents a significant step forward in the brick manufacturing industry. Its integration of advanced technology, automation, and sustainability highlights the company's commitment to innovation and responsible manufacturing practices. This development is poised to usher in a new era of efficiency, precision, and eco-consciousness in the brick manufacturing sector.

Top-Quality Brick, Roofing Tile and Wall Plant Manufacturing Services

Clay Brick Production Line: Revolutionizing the Construction IndustryThe construction industry has always been at the forefront of innovation and constant evolution. From architectural marvels to efficient building techniques, each new development caters to the ever-growing demands of the world's population. In this pursuit, the Clay Brick Production Line has emerged as a significant game-changer, offering unprecedented advantages in terms of efficiency, sustainability, and affordability. In this blog, we will delve into the intricacies of the Clay Brick Production Line and explore its impact on the construction industry.Before we delve into the production line, it is essential to understand the significance of clay bricks. Clay bricks have been a staple in construction for centuries, owing to their durability, strength, and versatility. Architects and builders have long relied on this traditional building material to erect long-lasting structures. However, with the advent of globalization and the rising demand for construction materials, the industry has witnessed a need for enhanced production capabilities. Enter the Clay Brick Production Line.The Clay Brick Production Line is a comprehensive and sophisticated system that encompasses the entire brick manufacturing process. From the initial preparation of clay to the packaging of finished products, this system ensures a smooth and efficient operation at every stage. One company, who specializes in this area, designs and manufactures bespoke Clay Brick Production Lines that cater to the unique needs and requirements of clients worldwide (brand name removed).The preparation stage of the production line is a critical component in ensuring the quality and consistency of the final product. High-quality clay is sourced and processed meticulously, removing any impurities or unwanted particles. The precisely controlled moisture content and particle size distribution guarantee optimal brick characteristics. This attention to detail during preparation sets the foundation for a successful and reliable production line.The extrusion stage is where the magic happens. The prepared clay is passed through an extruder, which shapes and molds the material into the desired brick form. This process can be fully automated, providing significant benefits in terms of efficiency and consistency. The extrusion stage also allows for customization, ensuring that each brick meets the specific requirements of the project at hand. The versatility and adaptability of the Clay Brick Production Line make it a valuable asset for any construction project.Once the bricks have been extruded, the cutting stage comes into play. Precise cutting techniques ensure that each brick is uniform in shape and size, guaranteeing seamless assembly during construction. Advanced machinery and cutting-edge technology minimize wastage and increase productivity. The Clay Brick Production Line also allows for the creation of various brick sizes and designs, providing architects and builders with unlimited possibilities for their creative vision.Packaging is the final step in the production line, ensuring the safe transportation and storage of the manufactured bricks. The Clay Brick Production Line offers customizable packaging solutions, tailored to individual project specifications. This attention to detail enables efficient logistics and reduces the risk of damage during transit, further cementing the advantages of this innovative system.The Clay Brick Production Line has revolutionized the construction industry in numerous ways. Firstly, efficiency is greatly enhanced due to automation and streamlined processes. With the ability to produce thousands of bricks per hour, the production line accelerates construction timelines, enabling builders to meet deadlines and complete projects promptly. Additionally, the reduced margin for error ensures consistent quality and minimizes rework, optimizing resource utilization.Another significant advantage of the Clay Brick Production Line lies in its sustainability credentials. Clay bricks are an inherently eco-friendly building material, and the automated production line enhances this attribute. Precise material control reduces waste, and optimized energy consumption makes the process highly energy-efficient. Furthermore, the longevity and durability of clay bricks contribute to the overall sustainability of constructed buildings.Affordability is also a key factor in the construction industry, and the Clay Brick Production Line delivers on this front as well. By streamlining processes and minimizing waste, the cost of production is substantially reduced. These cost savings can be passed on to builders and end-users, making clay bricks an attractive and accessible choice for construction projects of any scale.In conclusion, the Clay Brick Production Line has emerged as a groundbreaking solution that caters to the growing demands of the construction industry. With its comprehensive and efficient system, this production line ensures the production of high-quality clay bricks that meet the exact specifications of builders and architects worldwide. From preparation to extrusion, cutting, and packaging, every stage of the process is meticulously crafted to enhance efficiency, sustainability, and affordability. Embracing the Clay Brick Production Line is the key to revolutionizing the construction industry and building a sustainable future for generations to come.

Affordable and Efficient Brick Making Machine - Automates the Brick Production Process

In today’s fast-paced world, the need for efficient and cost-effective manufacturing is becoming increasingly important. From small startups to large-scale industrial corporations, businesses are continuously looking to automate their manufacturing processes to save time and reduce labour costs. With this in mind, the Automatic Brick Making Machine is fast becoming a popular solution to meet these needs.The Automatic Brick Making Machine is a high-tech solution specially designed for the manufacturing of bricks in large quantities. This machine uses hydraulic pressure and molds to create bricks from various materials such as clay, sand, cement, and fly ash. The process of manufacturing bricks using an Automatic Brick Making Machine is fast, efficient, and cost-effective.Leading the market in Automatic Brick Making Machines is a company that specializes in the manufacture of high-tech machines for various industries. The company, which shall remain nameless, prides itself in producing quality machines that are innovative, efficient, and user-friendly. With years of experience in the manufacturing sector, the company’s team of engineers and designers have been able to develop an Automatic Brick Making Machine that meets the expectations of their customers.One of the features that sets this Automatic Brick Making Machine apart is its ability to produce up to 20,000 bricks per hour. This allows businesses to produce large quantities of bricks at a fraction of the time and cost of traditional brick-making methods. Furthermore, the machine allows for customization of brick sizes and shapes, enabling businesses to meet specific market demands.Another benefit of the Automatic Brick Making Machine is the minimal labour required. The machine is fully automated, meaning that only a few staff members are required to operate it. This significantly reduces labour costs and allows businesses to free up staff to focus on other areas of the business.The Automatic Brick Making Machine is also environmentally friendly, using up to 90% less water than traditional brick-making methods. This dry process also means that there is no need for kiln firing, which further reduces the machine’s carbon footprint.Other features of the Automatic Brick Making Machine include its easy to operate system, which requires minimal training for staff, and its low maintenance requirements. The machine is built with high-quality materials, ensuring that it is durable and long-lasting.As business owners look for cost-effective solutions to meet their manufacturing needs, the Automatic Brick Making Machine is becoming increasingly popular. With its fast production speed, low labour costs, and environmentally friendly capabilities, it is a viable option for brick manufacturers looking to scale up their operations.In conclusion, the Automatic Brick Making Machine is a perfect solution for brick manufacturers. With its efficient and environmentally friendly features, it offers an efficient and cost-effective way of producing bricks in large quantities. The company behind the machine takes pride in their innovative and high-quality machines, which are designed to meet the needs of the consumers. It is clear that the Automatic Brick Making Machine is a game-changer for the brick manufacturing industry, and businesses that incorporate it into their manufacturing processes will undoubtedly reap the benefits.

Affordable Brick Making Machines for Sale

Brick Making Machine Provides Affordable Option for Construction IndustryAs the demand for housing and infrastructure construction continues to grow around the world, the cost of construction materials has become a major concern for builders and developers. In order to meet this demand and provide an affordable solution, a company specializing in brick making machines has recently launched a new affordable option for small and medium-sized construction projects.The company, which has been in the industry for over 20 years, has a proven track record of producing high-quality brick making machines for large scale operations. With the introduction of their new affordable model, smaller construction projects can now take advantage of the same advanced technology used in their larger machines."We understand the challenges facing smaller construction projects and our new machine is designed to provide an affordable and efficient option for them," said the company director. "In addition to lower cost, our machine is highly reliable and easy to use, allowing for faster production and reduced wastage."The new brick making machine is designed to be highly flexible, allowing it to produce a variety of different bricks and blocks to suit a wide range of building requirements. Its compact size also makes it easy to transport and set up, making it an ideal choice for small-scale construction sites.One of the key advantages of the machine is its ability to produce interlocking bricks, which offer significant cost savings compared to traditional bricks. Interlocking bricks do not require mortar and can be assembled easily using an interlocking system, reducing labor costs and construction time."The interlocking brick technology is becoming increasingly popular around the world as its benefits become more widely recognized," said the director. "Our machine has been specifically designed to produce these bricks, allowing even smaller construction projects to take advantage of this cost-saving technology."The machine is also equipped with advanced automation technology, allowing for precise control over the production process and minimizing the risk of errors. It is also highly energy-efficient and environmentally friendly, with low emissions and minimal noise pollution."Environmental sustainability is a key consideration for our company and we are proud to be able to offer a machine that meets these requirements," said the director. "Not only is it good for the environment, but it also helps our customers to reduce their energy costs and operate more efficiently."Overall, the new affordable brick making machine is an attractive option for small and medium-sized construction projects looking to reduce costs and increase efficiency. With its advanced technology, flexibility, and environmental benefits, it is expected to become a popular choice in the industry."We believe that our new machine offers a unique value proposition for the construction industry and are confident that it will become a game-changer in the market," said the director. "By providing an affordable and high-quality option for smaller projects, we are helping to drive growth and innovation in the industry.

Advanced Hydraulic Brick Making Machine for Creating Various Concrete Products

, Fly Ash Brick Making Machine, Concrete Interlocking Brick Making Machine.Clay Hollow Brick Machine – Revolutionizing The Construction Industry!In the construction industry, brick-making plays a crucial role. Bricks are an essential component of the structure of any building. Clay, flyash, cement, gravel, and other raw materials are used to make bricks. Construction workers have been using traditional brick-making techniques for centuries, which is both time-consuming and laborious.But with the advent of technology, innovation, and modern engineering, brick-making machines have come a long way. Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine is one of the most revolutionary products that have hit the construction industry in recent times. This machine is capable of producing all types of bricks at an impressive speed, thereby reducing the time and labor required to make bricks.Technical Specifications Of QTJ4-15 Block Brick Making MachineThe Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine comes packed with many impressive features and specifications. Let’s take a closer look at some of the technical specifications of this machine:Product Quantity390190190 4pcs/mould24011552 26pcs/mould24011590 (need remove brand name)Raw MaterialsThe machine uses a variety of raw materials, which include crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. These raw materials are mixed to form the perfect combination that makes bricks of all types and sizes.Applied ProductsThe Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine can produce various types of bricks such as Solid / hollow / cellular masonry products, paving stones, garden and landscaping products, slabs, kerbstones, grass blocks, slope blocks, interlocking blocks, and many more. This machine is versatile and can be used in various construction projects.Applied FieldsThe Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine is widely used in buildings, road pavers, squares, gardens, landscaping, city constructions, and many other construction projects.Advantages Of Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making MachineThe Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine offers several advantages over traditional brick-making techniques. Let’s take a look at some of them:1. Faster Production – The machine can produce bricks at an impressive speed of up to 8000 pieces per day, which is almost ten times faster than traditional brick-making techniques. This means that construction projects can be completed faster, reducing the overall construction time and cost.2. Consistency – The machine produces bricks of consistent quality and size, ensuring that the construction project is uniform and aesthetically pleasing.3. Environmentally Safe – The machine uses fly ash, a by-product of coal combustion, to make bricks. This means that the machine is environmentally safe and does not contribute to air or water pollution.4. Low Labour Cost - With Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine, the cost of labour is significantly reduced as it requires only a few workers to operate the machine. This contributes to reducing the overall cost of the construction project.ConclusionThe Hydraulic Automatic Fly Ash Cement Concrete Interlocking Hollow Clay Brick Making Machine is a game-changer in the construction industry. With its impressive speed, consistency, and environmental safety, this machine is quickly becoming one of the most preferred options in the industry. If you are looking to reduce your construction time, cost, and labour while maintaining the highest quality standards, this machine is the perfect choice for you.

Exploring the Advantages of Soil Bricks Machinery for Sustainable Construction

Title: Revolutionizing Construction: Soil Bricks Machinery Pioneers Sustainable Building SolutionsIntroduction:In an era marked by increasing environmental concerns and a pressing need for sustainable development, Soil Bricks Machinery has emerged as a trailblazer in the construction industry. By leveraging innovative technology, this pioneering company aims to revolutionize traditional building methods and pave the way for a greener, more sustainable future.Company Overview:Soil Bricks Machinery is a leading provider of state-of-the-art equipment and machinery designed for the production of soil bricks. The company has established itself as a key player in the industry, with a comprehensive product line that caters to diverse construction needs. By combining cutting-edge technology, eco-conscious practices, and a commitment to quality, Soil Bricks Machinery has become synonymous with sustainable construction solutions.1. Sustainable Practices:Soil Bricks Machinery is guided by a deep-rooted commitment to the environment. Unlike conventional brick production, which heavily relies on resource-intensive processes, the company's machinery harnesses the power of natural materials, such as soil and clay, to create sturdy and eco-friendly bricks. By minimizing energy consumption and reducing carbon emissions during the manufacturing process, Soil Bricks Machinery offers builders an alternative that is both sustainable and cost-effective.2. Innovative Designs:The machinery developed by Soil Bricks Machinery offers unparalleled versatility, enabling builders to create unique and aesthetically pleasing architectural designs. The company's cutting-edge technology allows for precise manufacturing, resulting in bricks with superior quality and uniformity. This level of precision ensures stability and durability in buildings, providing added value to both homeowners and contractors.3. Cost-Effectiveness:One of the key advantages of Soil Bricks Machinery lies in its cost-effectiveness. By utilizing locally available soil and decreasing the demand for traditional clay bricks, builders can significantly reduce construction costs. Additionally, the machinery is designed for maximum efficiency, minimizing material waste and optimizing production capacity. This makes Soil Bricks Machinery an ideal choice for large-scale construction projects, ultimately enhancing profitability for developers.4. Job Creation and Empowerment:Soil Bricks Machinery acknowledges the importance of social empowerment and job creation. The company actively promotes skill development by offering training programs for aspiring builders and technicians. By equipping individuals with the knowledge and expertise required for soil brick production, Soil Bricks Machinery not only contributes to local economies but also empowers communities through sustainable employment opportunities.5. Environmental Impact:The widespread adoption of Soil Bricks Machinery's technology has the potential to make a significant impact on the environment. By shifting away from traditional brick manufacturing methods that contribute to deforestation and pollution, this innovative approach mitigates negative ecological effects. Using soil as a primary resource for brick production also reduces the strain on landfills by minimizing waste accumulation, further contributing to the overall well-being of our planet.Conclusion:Soil Bricks Machinery has revolutionized the construction industry by providing sustainable and cost-effective building solutions. Through their state-of-the-art machinery, the company enables builders to produce high-quality and environmentally friendly bricks, reducing the dependence on traditional clay bricks. With a deep commitment to sustainable practices, innovative designs, and a focus on social empowerment, Soil Bricks Machinery leads the charge towards a greener and more prosperous future.