Efficient and Sustainable Earth Block Machine for Construction Projects

By:Admin

The construction industry is rapidly changing as the world becomes more conscious of the environmental impact of traditional building materials and methods. In response to this shift, a growing number of companies are embracing sustainable solutions that prioritize eco-friendly practices.

One such company, based in [location], has been at the forefront of the sustainable construction movement. With a commitment to innovation and environmental responsibility, they have developed a groundbreaking technology that has the potential to revolutionize the way buildings are constructed.

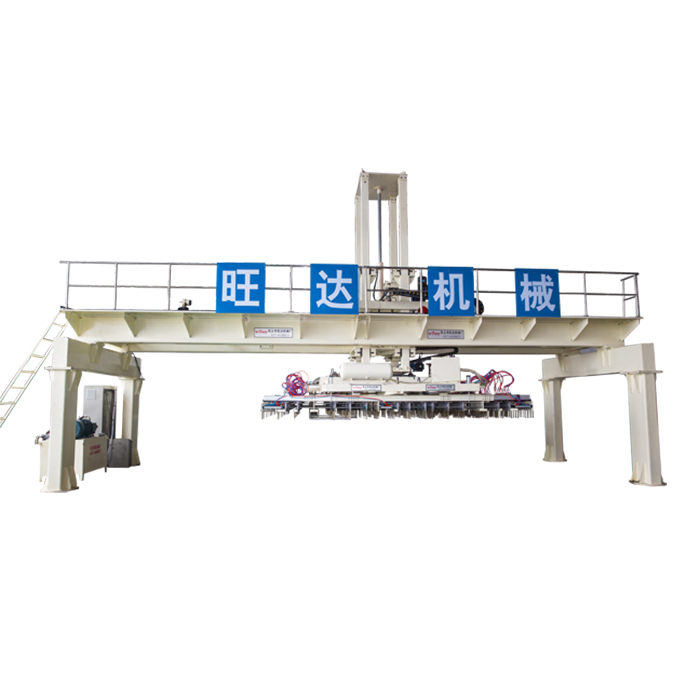

Their Earth Block Machine is a cutting-edge piece of equipment that enables the production of blocks made from locally sourced earth, cement, and water. These blocks are not only incredibly durable and energy-efficient, but they also have a significantly lower carbon footprint than traditional building materials such as concrete and bricks. By utilizing the Earth Block Machine, construction companies can reduce their environmental impact and contribute to the global effort to combat climate change.

In addition to its environmental benefits, the Earth Block Machine is also a game-changer in terms of affordability and accessibility. Traditional building materials can be expensive and often require importing, adding to the overall cost and carbon footprint of a project. With the Earth Block Machine, construction companies can produce high-quality, sustainable building blocks on-site, using locally available materials. This not only reduces costs but also supports local economies and reduces the need for transportation, further reducing the project's environmental impact.

The company behind this innovative technology has a long-standing commitment to sustainability and social responsibility. By focusing on eco-friendly practices and community engagement, they have set themselves apart as leaders in the sustainable construction industry. Their Earth Block Machine is just one example of their dedication to creating solutions that prioritize environmental and social well-being.

Furthermore, the company is dedicated to providing comprehensive support and training to those interested in utilizing the Earth Block Machine. They offer training programs and technical assistance to ensure that construction companies can effectively implement this technology into their projects. By doing so, they are not only promoting the use of sustainable building materials but also supporting the development of local construction industries around the world.

The impact of the Earth Block Machine extends beyond its environmental and economic benefits. By promoting the use of sustainable building materials, this technology has the potential to improve living conditions in communities around the world. The durability and thermal properties of the blocks produced by the Earth Block Machine make them an ideal choice for affordable, energy-efficient housing. As a result, this technology has the potential to address housing shortages and improve the quality of life for countless individuals and families.

The Earth Block Machine is a prime example of the power of innovation and sustainability in the construction industry. By providing a reliable and eco-friendly alternative to traditional building materials, this technology has the potential to reshape the way buildings are constructed. With a commitment to environmental responsibility and community empowerment, the company behind the Earth Block Machine is leading the way towards a more sustainable and equitable future.

As the global construction industry continues to evolve, it is clear that sustainable solutions like the Earth Block Machine will play a crucial role in shaping its future. With its potential to lower carbon emissions, reduce costs, and improve living conditions, this groundbreaking technology has the power to transform the way we build and live. As more companies and communities embrace sustainable construction practices, the Earth Block Machine stands as a shining example of the positive impact that innovation and environmental responsibility can have on the world.

Company News & Blog

Semi Automatic Clay Brick Making Machine: A Game-Changer for Brick Production

Semi Automatic Clay Brick Making Machine revolutionizes the manufacturing process for clay bricks. The innovative technology automates the brick making process, increasing efficiency and reducing manual labor. This state-of-the-art machine is a game-changer for the construction industry, offering a cost-effective and sustainable solution for producing high-quality clay bricks.The Semi Automatic Clay Brick Making Machine is equipped with advanced features that streamline the production process. The machine is capable of producing a large volume of bricks in a short period, making it ideal for large-scale construction projects. The automation of the brick making process eliminates the need for manual labor, reducing the risk of human error and increasing overall productivity.In addition to its efficiency, the Semi Automatic Clay Brick Making Machine also prioritizes sustainability. The machine is designed to minimize energy consumption and waste, making it an environmentally friendly option for brick production. By using clay as the primary raw material, the machine ensures that the bricks produced are durable and long-lasting, contributing to the sustainability of construction projects.The company behind the Semi Automatic Clay Brick Making Machine is dedicated to providing innovative solutions for the construction industry. With years of experience and expertise in manufacturing machinery, the company has set a new standard for brick making technology. Their commitment to quality and efficiency is evident in the design and functionality of the Semi Automatic Clay Brick Making Machine.The company's dedication to sustainability is also reflected in the Semi Automatic Clay Brick Making Machine. By prioritizing energy efficiency and waste reduction, the machine aligns with global efforts to promote environmentally friendly manufacturing processes. This commitment to sustainability sets the company apart as a leader in the industry, positioning them as a go-to source for innovative and eco-friendly construction solutions.The Semi Automatic Clay Brick Making Machine has already garnered attention from construction companies and builders around the world. Its advanced technology and sustainability features make it an attractive option for those seeking to enhance their production capabilities while minimizing their environmental impact. With its ability to produce high-quality clay bricks at a rapid pace, the machine offers a competitive advantage for any construction project.The company's dedication to innovation and sustainability sets a new standard for the construction industry. By introducing the Semi Automatic Clay Brick Making Machine, they have demonstrated their commitment to providing cutting-edge solutions that benefit both businesses and the environment. As the demand for sustainable construction practices continues to grow, the company's emphasis on eco-friendly manufacturing technology positions them as a key player in the industry.In conclusion, the Semi Automatic Clay Brick Making Machine represents a significant advancement in the construction industry. Its innovative technology, efficiency, and sustainability features make it an attractive option for construction companies looking to streamline their brick production process. With the company's commitment to providing high-quality and eco-friendly solutions, the machine is poised to make a lasting impact on the way clay bricks are manufactured.

Ultimate Guide to Clay Brick Plant: Production, Process and Applications

The Clay Brick Plant, located in (insert location), is a state-of-the-art facility that has been producing high-quality clay bricks for over 20 years. With a focus on innovation and sustainability, the plant has become a leader in the industry and is continuously working towards reducing its environmental impact.The plant utilizes the latest technology and equipment to ensure that the clay bricks produced are of the highest quality. The production process begins with the extraction of raw materials from the surrounding area, which are then carefully processed and molded into bricks. The plant is able to produce a wide range of bricks, including standard bricks, pavers, and specialized bricks for specific architectural needs.In addition to producing high-quality bricks, the plant is also committed to sustainability. This includes implementing energy-efficient practices, recycling waste materials, and minimizing water usage. The plant is also constantly researching and implementing ways to reduce its carbon footprint and overall environmental impact. By prioritizing sustainability, the plant is able to not only produce high-quality bricks, but also to do so in a way that is environmentally responsible.The Clay Brick Plant is a major employer in the area, providing stable jobs for a large number of local residents. The plant also plays an important role in supporting the local economy by sourcing raw materials from local suppliers and contributing to the overall growth of the community.As a leader in the industry, the plant is also committed to ongoing research and development. This includes investing in new technologies and processes to further improve the quality of its bricks and reduce its environmental impact. By staying at the forefront of innovation, the plant is able to stay competitive in the market and continue to meet the needs of its customers.With a focus on quality, sustainability, and innovation, the Clay Brick Plant has established itself as a leader in the industry. Its commitment to producing high-quality bricks in an environmentally responsible manner has set it apart from its competitors and has made it a trusted name in the construction industry.In conclusion, the Clay Brick Plant is a shining example of a company that is able to balance quality, sustainability, and innovation. With a focus on producing high-quality bricks while also minimizing its environmental impact, the plant has become a leader in the industry and a trusted name in the construction market. As it continues to invest in new technologies and processes, the plant is well-positioned to remain a leader in the industry for many years to come.

Revolutionizing the Clay Brick Making Industry: Unveiling the Future of Machinery

article.Clay Brick Making Machinery - The Ultimate Solution for High-Quality BricksAccording to the latest report, the demand for high-quality, durable bricks is increasing rapidly worldwide. Brick making is one of the oldest and most traditional manufacturing processes, and it is still a vital industry in today's modern society. In the past, brick making was done by hand, but nowadays, machinery has replaced much of the manual work.One of the world's leading manufacturers of Brick Making Machinery (need remove brand name) has taken the lead in developing high-quality and innovative equipment that provides ultimate solutions for brick making. The company has been producing brick making machinery for over 80 years and has established an excellent reputation for providing professional services to their clients.The company's machinery is designed to produce a wide range of bricks, including standard bricks, perforated bricks, decorative bricks, and interlocking bricks. The equipment can also handle a range of materials, including clay, fly ash, coal gangue, and shale. The Brick Making Machinery (need remove brand name) is suitable for brick making plants of all sizes, from small home-based operations to larger scale industrial facilities.One of the critical advantages of using the Brick Making Machinery (need remove brand name) is that it can produce bricks that are of a consistently high quality. The consistency of the bricks is achieved through the use of advanced technology that controls the temperature and moisture levels during the manufacturing process. The equipment is also designed with high precision, ensuring that each brick is identical to the next in both size and shape.Another significant advantage of the Brick Making Machinery (need remove brand name) is its versatility. The machinery can produce various types of bricks with ease, depending on the needs of the client. This feature makes the equipment particularly appealing to small to medium-sized brick-making enterprises, which require flexibility in their production processes.The company behind the Brick Making Machinery (need remove brand name) is committed to providing professional services that exceed their client's expectations. The manufacturer's team of skilled technicians provides comprehensive installation services for the equipment, which includes training on the use and maintenance of the equipment. The company offers round-the-clock technical support to ensure the reliable and optimal production of bricks.The company's commitment to quality is further reinforced by their development of environmentally friendly brick making machinery. The equipment is designed to comply with environmental regulations and reduce the carbon footprint of brick making. The Brick Making Machinery (need remove brand name) is equipped with advanced filtration systems that limit dust and emissions, ensuring that the manufacturing process is as environmentally friendly as possible.The Brick Making Machinery (need remove brand name) has gained worldwide recognition for its quality and reliability. The machinery is used in brick-making plants in many countries, including India, South Africa, Russia, and South America. The equipment's reputation is based on its effectiveness, efficiency, and affordability, making it a sound investment for any brick-making enterprise.In conclusion, the Brick Making Machinery (need remove brand name) offers the ultimate solution for the production of high-quality bricks. The equipment is versatile, reliable, and environmentally friendly, making it ideal for small to medium-sized enterprises. The company's commitment to quality and customer service is second to none, and their 80 years of experience in the industry is a testament to their expertise. Investing in Brick Making Machinery (need remove brand name) is a smart choice for anyone looking to build a successful brick making business.

Compact Brick Making Machine Takes the Construction Industry by Storm

Mini Brick Making Machine: A New Era of Sustainable and Efficient ConstructionThe construction industry has seen significant changes in the past years, not only in terms of the technologies used but also in terms of the focus on sustainability and efficiency. From green energy solutions to the adoption of eco-friendly construction materials, the industry is continuously exploring innovative ways to minimize environmental impact and optimize productivity. In line with this pursuit for progress, a new player is entering the scene – the Mini Brick Making Machine (MBMM). This innovative machine is poised to revolutionize the way we build structures, bringing about a new era of sustainable and efficient construction.What is the Mini Brick Making Machine?The Mini Brick Making Machine is a compact, portable machine that is used to manufacture bricks on-site. It is suitable for small to medium-sized construction projects such as homes, commercial buildings, and even road works. It is powered by electrical motors, which makes it environmentally friendly and cost-efficient. The machine is designed to produce up to 1000 bricks per hour, which means faster delivery and reduced construction time. It is also easy to operate, with a user-friendly interface that can be operated by just one person.The Advantages of Using the Mini Brick Making MachineOne of the key advantages of using the Mini Brick Making Machine is its environmental friendliness. The machine is powered by electrical motors, which means that it doesn't produce any harmful emissions that can contribute to air pollution. This makes it a more sustainable and eco-friendly alternative to traditional brick-making methods, which rely heavily on fossil fuels and other non-renewable resources.Another advantage of using the Mini Brick Making Machine is its cost-efficiency. The machine eliminates the need for transporting bricks from one location to another, which can be costly and time-consuming. By producing bricks on-site, construction companies can save on transportation costs and reduce the delivery time of construction materials. This, in turn, can result in significant cost savings that can be passed on to clients.The Mini Brick Making Machine is also known for its high quality and durability. The machine is designed to produce bricks that are uniform in size and shape, which ensures that the finished construction is strong and sturdy. It is also made from high-quality materials that are built to withstand wear and tear, making it a reliable investment for construction companies.Company IntroductionThe company that manufactures the Mini Brick Making Machine is a family-owned business that has been operating for over 30 years. They specialize in the design, manufacturing, and distribution of construction equipment and machinery. The company prides itself on delivering high-quality products that are innovative, cost-efficient, and sustainable. They have a team of experienced engineers and technicians who are dedicated to ensuring that their products are at the forefront of construction technology.The Mini Brick Making Machine is just one of the many products that the company offers. They also provide a range of other construction equipment, including concrete mixers, vibrators, and scaffolding. All of their products are designed with the aim of helping construction companies achieve optimal productivity while minimizing environmental impact.ConclusionThe Mini Brick Making Machine is an exciting innovation in the construction industry, offering a more sustainable and efficient way of producing bricks. With its cost-efficiency, high quality, and ease of operation, the machine is poised to become a game-changer in the industry. Its environmental friendliness is also a huge advantage, making it a more sustainable alternative to traditional brick-making methods. With the backing of an experienced and dedicated company, the Mini Brick Making Machine will surely make waves in the construction industry, paving the way for a more sustainable and efficient future.

How to Choose the Best Small Brick Making Machine for Your Business Needs

Small Brick Making Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving with the introduction of new technologies and innovations. One such innovation that is making waves in the industry is the small brick making machine. This state-of-the-art machine is revolutionizing the way bricks are made, offering a more efficient and cost-effective solution for construction projects.The small brick making machine, manufactured by an industry-leading company, has quickly gained popularity in the construction market due to its compact size and powerful capabilities. This innovative machine is designed to produce high-quality bricks at a rapid pace, significantly reducing the time and cost required for brick production.The company behind this groundbreaking technology is committed to providing sustainable and eco-friendly solutions for the construction industry. With a focus on innovation and quality, they have developed a small brick making machine that not only improves efficiency but also reduces the environmental impact of brick production.The machine is designed to be user-friendly, allowing operators to easily produce bricks with minimal training or experience. Its compact design makes it suitable for small-scale construction projects, where traditional brick-making processes may be impractical or cost-prohibitive. This versatility has made the small brick making machine a game-changer for builders and contractors looking for efficient and affordable solutions.In addition to its efficiency and ease of use, the small brick making machine also boasts impressive output capabilities. With the ability to produce a large number of bricks in a short amount of time, this machine has become an essential tool for construction projects that require a steady supply of high-quality bricks.Furthermore, the small brick making machine is designed to minimize waste and maximize the use of raw materials. Its advanced technology ensures that bricks are produced with precision and consistency, resulting in less material wastage and higher overall quality. This not only reduces the environmental impact of brick production but also helps to save costs for construction companies.The company's commitment to sustainability extends beyond the design of the small brick making machine. They also offer comprehensive training and support to their clients, ensuring that operators are able to maximize the machine's capabilities while adhering to best practices for environmentally responsible production.Moreover, the small brick making machine is equipped with advanced features that enhance its performance and reliability. From automated controls to high-powered motors, this machine is built to withstand the demands of heavy-duty construction work while maintaining its efficiency and quality output.With its innovative design, eco-friendly approach, and impressive capabilities, the small brick making machine is quickly becoming the go-to solution for construction companies around the world. Its ability to streamline brick production, reduce costs, and minimize environmental impact has garnered attention from industry professionals seeking modern and sustainable construction solutions.As the construction industry continues to embrace technological advancements, the small brick making machine is setting a new standard for efficiency and sustainability. With its potential to revolutionize brick production and construction practices, this innovative machine is poised to reshape the way buildings are constructed for years to come.

Germany Design Fully Automatic Qt6 Concrete Cement Block Brick Making Machine - Interlock Paving Machine | Mechanical Kingdom

The Germany Design Fully Automatic Qt6 Concrete Cement Block Brick Making Machine is a mechanical machine used for producing various types of concrete blocks and bricks. This machine has high production capacity and can produce different shapes and sizes of blocks and bricks.The main technical specifications of the machine are as follows:- Production per Mould: The machine can produce 6 pieces of standard blocks (400x200x200mm) per mould, 30 pieces of solid blocks (240x115x53mm) per mould, 15 pieces of interlock pavers (225x112.5x60mm) per mould, and 21 pieces of Holland bricks (200x100x60-80mm) per mould.- Cycle Time: The machine has a cycle time of 15-20 seconds, which means it can produce blocks and bricks at a fast rate.- Production per Day (8 Working Hours): Depending on the type of block or brick being produced, the machine can produce a significant number of units per day. For example, it can produce 8640-11520 hollow blocks (400x200x200mm) per day, 43200-57600 solid blocks (240x115x53mm) per day, 17280-21600 interlock pavers (225x112.5x60mm) per day, and 2419230240 Holland bricks (200x100x60-80mm) per day.- Vibrating Frequency: The machine has a vibrating frequency of 3300 rolls per minute, which helps in compacting the concrete mixture and ensuring the quality of the blocks and bricks.- Vibrating Force: The machine generates a vibrating force of 60 KN, which further aids in the compaction process.- Motors Power: The machine is powered by a 30 KW motor, which provides the necessary power for the various operations.- Machine Dimensions: The machine has dimensions measuring 9680x2800x2800mm. This size allows it to efficiently produce the desired blocks and bricks.- Pallet Size: The machine uses pallets with dimensions of 850x680mm to hold and transport the produced blocks and bricks.- Gross Weight: The machine has a gross weight of approximately 7.5T, ensuring stability during operation.- Raw Materials: The machine can utilize a variety of raw materials including crushed stone, sand, cement, dust, coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. These materials are mixed together to form the concrete mixture used in block and brick production.- Applied Products: The machine can produce a wide range of concrete products including concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, and grass paving.In conclusion, the Germany Design Fully Automatic Qt6 Concrete Cement Block Brick Making Machine is a highly efficient and versatile machine suitable for large-scale production of different types of concrete blocks and bricks. Its high production capacity, fast cycle time, and ability to handle various raw materials make it a valuable asset in the construction industry.

Top-quality Brick Machine Factory: Everything You Need to Know

Brick Machine Factory, a leading manufacturer of brick making machinery, has been making waves in the construction industry with its innovative and high-quality products. With a strong focus on research and development, the company has been able to continuously improve its machines to meet the evolving needs of the market.Established in 2005, Brick Machine Factory has quickly gained a reputation for its commitment to excellence and customer satisfaction. The factory is equipped with state-of-the-art technology and employs a team of skilled engineers and technicians who work tirelessly to design and produce top-of-the-line brick making machines.The company offers a wide range of brick making machines, including fully automatic, semi-automatic, and manual models, to cater to the diverse needs of its customers. Its machines are known for their durability, high productivity, and low maintenance, making them the preferred choice for construction companies and contractors around the world.In addition to its standard models, Brick Machine Factory also provides customization options, allowing customers to tailor the machines to their specific requirements. This flexibility has set the company apart from its competitors and has further solidified its position as a market leader in the brick making machinery industry.Furthermore, Brick Machine Factory takes pride in its commitment to sustainability. The company has invested heavily in developing environmentally friendly brick making machines that minimize energy consumption and reduce waste. This demonstrates its dedication to making a positive impact on the environment while delivering top-quality products to its customers.In recent years, Brick Machine Factory has expanded its global presence and has successfully established partnerships and distribution channels in several countries. Its dedication to quality and customer service has earned it a loyal customer base and has paved the way for further growth and success in the international market.The company's success can also be attributed to its continuous investment in research and development. By staying ahead of the curve and anticipating market trends, Brick Machine Factory has been able to introduce cutting-edge technologies and features in its machines, offering customers the most advanced and efficient solutions for their brick making needs.As the demand for sustainable and cost-effective construction solutions continues to grow, Brick Machine Factory is well-positioned to capitalize on this trend. The company's unwavering commitment to innovation and customer satisfaction sets it apart in the competitive landscape of the brick making machinery industry.Looking ahead, Brick Machine Factory is poised for further expansion and success as it continues to push the boundaries of technology and quality in the manufacturing of brick making machines. With a solid foundation built on expertise, reliability, and sustainability, the company is well-equipped to meet the evolving needs of the construction industry and maintain its leadership position in the global market.

Top 10 Brick Machine Manufacturers to Consider for Your Construction Needs

Brick Machine Manufacturers are renowned for their high-quality products and innovative technology in the field of brick making. With a strong focus on customer satisfaction and continual improvement, the company has established itself as a leader in the industry.Founded in [year], {Company Name} has been at the forefront of developing and manufacturing brick machines that are efficient, durable, and highly productive. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing for the production of cutting-edge brick making machines that meet the needs of their diverse clientele.One of the key factors that set {Company Name} apart from its competitors is its commitment to research and development. The company invests heavily in R&D to continually improve its products and develop new technologies that push the boundaries of brick making. This dedication to innovation has enabled {Company Name} to stay ahead of the curve and provide its customers with the most advanced brick machines on the market.In addition to its technical prowess, {Company Name} places a strong emphasis on customer satisfaction. The company understands that each client has unique needs and works closely with them to provide tailor-made solutions that meet their specific requirements. Whether it's selecting the right brick machine for a particular project or providing ongoing technical support, {Company Name} is dedicated to delivering the highest level of service to its customers.Furthermore, {Company Name} is committed to sustainability and environmental responsibility. The company's brick machines are designed to be energy-efficient and minimize waste, helping to reduce the environmental impact of brick production. By offering eco-friendly solutions, {Company Name} is contributing to a more sustainable future for the brick making industry.Recently, {Company Name} announced the launch of its latest innovation: the XYZ Brick Machine. This cutting-edge machine incorporates the latest advancements in brick making technology, offering unmatched efficiency and productivity. The XYZ Brick Machine is designed to meet the demands of modern brick production while maintaining the high quality and durability that {Company Name} is known for."We are thrilled to introduce the XYZ Brick Machine to the market," said [Spokesperson Name], CEO of {Company Name}. "This machine represents the culmination of years of hard work and dedication to pushing the boundaries of brick making technology. We believe that the XYZ Brick Machine will set a new standard for efficiency and productivity in the industry."The XYZ Brick Machine is set to revolutionize brick production with its advanced features, including automated operation, precision molding, and high-speed output. With the ability to produce a wide range of brick sizes and types, this machine is versatile enough to meet the needs of various projects and applications.In addition to the XYZ Brick Machine, {Company Name} has also unveiled a new line of accessories and support services to complement its machines. This includes advanced molds, cutting-edge automation technology, and comprehensive training programs to help customers maximize the performance of their brick machines.As {Company Name} continues to push the boundaries of brick making technology, the company remains committed to its core values of excellence, innovation, and customer satisfaction. With a track record of success and a dedication to continual improvement, {Company Name} is poised to remain a leader in the brick making industry for years to come.

Top Quality Brick Machine Available in India: Find Out More

The brick making industry in India has seen a significant technological advancement with the introduction of advanced brick making machines. These machines have revolutionized the traditional brick making process and are helping to increase efficiency and productivity in the brick manufacturing sector.One of the key players in this industry is a company that has been at the forefront of developing innovative and high-quality brick making machines. With their state-of-the-art technology and commitment to research and development, they have become a trusted name in the brick making machinery market.The company's brick making machines are known for their robust construction, high efficiency, and user-friendly operation. They offer a wide range of machines that cater to the diverse needs of brick manufacturers, including automatic, semi-automatic, and manual machines. Their machines are also designed to produce various types of bricks such as concrete, clay, fly ash, and interlocking bricks.The brick making machines from this company are equipped with advanced features such as automatic material feeding, mold vibrating, and hydraulic pressing, which ensure consistent and high-quality brick production. These machines also have a high production capacity, allowing brick manufacturers to meet the growing demand for bricks in the construction industry.One of the key advantages of using these machines is their energy efficiency and cost-effectiveness. The company has incorporated energy-saving technologies in their machines, which not only reduce the overall operational costs but also contribute to environmental sustainability.Furthermore, the company provides comprehensive after-sales support to its customers, including installation, training, and maintenance services. This ensures that brick manufacturers can maximize the performance and lifespan of their machines, leading to long-term cost savings and operational efficiency.Recently, the company has launched a new range of brick making machines that are specifically tailored to the needs of the Indian market. These machines have been designed to address the challenges faced by brick manufacturers in India, such as the availability of raw materials, labor costs, and environmental regulations.The new range of machines incorporates innovative technologies that help reduce the usage of natural resources, minimize waste generation, and optimize the production process. Additionally, these machines are designed to be more compact and mobile, making them suitable for small-scale brick manufacturing operations in rural areas.The company has also expressed its commitment to supporting the Indian government's initiatives for promoting sustainable and eco-friendly construction practices. They are actively involved in research and development activities to create more advanced and environmentally friendly brick making machines that align with the government's vision for a cleaner and greener India.With the introduction of these advanced brick making machines, the Indian brick manufacturing industry is set to witness a significant transformation. These machines will not only improve the overall productivity and quality of bricks but also contribute to the sustainable development of the construction sector in India.In conclusion, the company's commitment to innovation and sustainability has positioned them as a leading provider of advanced brick making machines in India. Their machines are making a positive impact on the brick manufacturing industry by increasing efficiency, reducing costs, and promoting environmental responsibility. As the demand for high-quality bricks continues to rise in India, these advanced machines are expected to play a critical role in shaping the future of the brick making industry in the country.

Efficient and Automated Brick Factory Streamlines Production Processes

Automatic Brick Factory Revolutionizes the Brick-making IndustryThe brick-making industry has seen a revolutionary change with the introduction of the cutting-edge Automatic Brick Factory, a groundbreaking innovation that has set the bar high for efficiency, productivity, and quality in the manufacturing of bricks.This state-of-the-art factory, developed by a leading construction machinery manufacturer, incorporates advanced technology and automation to streamline the brick-making process. With its fully automated system, the factory has significantly reduced the reliance on manual labor, minimizing human error and increasing production output. This has resulted in a remarkable increase in the overall efficiency of brick production.The Automatic Brick Factory is equipped with a range of sophisticated machinery and equipment, including automatic brick-making machines, robotic systems for handling and stacking bricks, conveyor belts for material transportation, and computerized control systems for monitoring and managing the entire production process. This level of automation has not only boosted the speed of production but has also enhanced the precision and consistency of the bricks being manufactured.One of the key features of this advanced factory is its ability to produce a wide variety of bricks with different sizes, shapes, and textures. This flexibility is made possible through the implementation of customizable molds and templates that can be easily adjusted to meet the specific requirements of different construction projects. As a result, the factory is capable of catering to the diverse needs of the construction industry, offering a comprehensive range of high-quality bricks for various applications.Furthermore, the Automatic Brick Factory is designed with a strong focus on sustainability and environmental responsibility. The factory operates with a reduced carbon footprint, thanks to its energy-efficient machinery and systems. Additionally, efforts have been made to optimize the use of raw materials and minimize waste generation, contributing to a more eco-friendly approach to brick production.In addition to its impressive technological capabilities, the Automatic Brick Factory also boasts a high level of productivity. With its ability to operate around the clock, the factory can consistently produce a large volume of bricks to meet the demands of the market. This is particularly advantageous for large-scale construction projects that require a continuous and reliable supply of bricks within tight timelines.Another notable aspect of the Automatic Brick Factory is its commitment to quality control. The factory employs stringent quality assurance measures to ensure that every brick that leaves the production line meets the highest standards of durability, strength, and consistency. This dedication to quality has earned the factory a reputation for delivering top-notch bricks that are trusted and favored by construction professionals.The introduction of the Automatic Brick Factory has had a profound impact on the brick-making industry. Its innovative approach to manufacturing has redefined the conventional methods of brick production, setting a new benchmark for excellence in the industry. As a result, construction companies and builders now have access to a reliable source of premium-quality bricks that are produced with precision and efficiency.In conclusion, the Automatic Brick Factory has emerged as a game-changer in the brick-making sector, offering a blend of cutting-edge technology, sustainable practices, high productivity, and uncompromising quality. Its contribution to the construction industry is undeniable, as it continues to shape the landscape of modern construction with its superior bricks and innovative manufacturing processes. This revolutionary factory is not just a milestone in the evolution of brick-making; it is a testament to the power of innovation and technology in transforming traditional industries for the better.