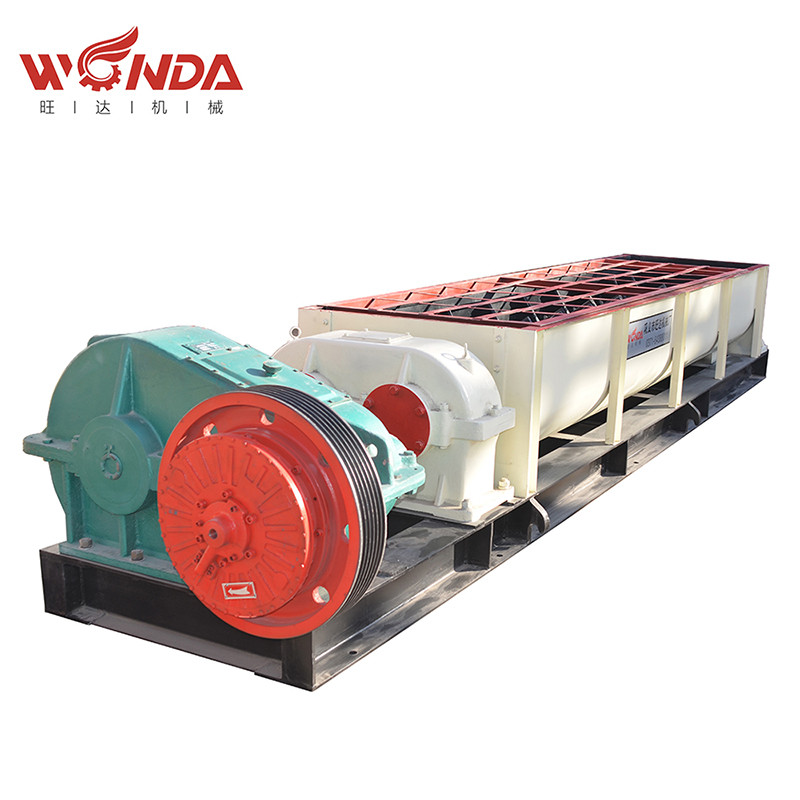

High-Quality Red Brick Making Machines Available for Purchase

By:Admin

The demand for red bricks in the construction industry continues to rise, creating a need for advanced brick making machines. In response to this, a leading company specializing in manufacturing industrial machinery has announced the availability of state-of-the-art red brick making machines for sale.

With over [number] years of experience in the industry, [Company] has established a solid reputation for producing high-quality and efficient brick making machines. The company takes pride in its commitment to innovation and technology, constantly updating its products to meet the evolving needs of the market.

The red brick making machines offered by [Company] are designed to be user-friendly, ensuring that even individuals with minimal technical knowledge can operate them with ease. They are also known for their durability, with a focus on using high-quality materials and components to ensure longevity and reliability.

One of the key features of [Company]'s red brick making machines is their ability to produce bricks of consistent size and shape, meeting the strict standards required for construction projects. This ensures that the bricks produced are of uniform quality, contributing to the overall durability and aesthetic appeal of the structures they are used in.

The machines also come equipped with advanced automation technology, allowing for efficient and cost-effective production. This is particularly important in the current market, where construction companies are looking for ways to streamline their operations and reduce production costs.

In addition to their technical capabilities, [Company]'s red brick making machines are also designed with environmental sustainability in mind. They are equipped with energy-efficient components and are engineered to minimize waste, making them a responsible choice for environmentally conscious construction businesses.

Customers who invest in [Company]'s red brick making machines can also expect comprehensive support and after-sales service. The company provides training and technical assistance to ensure that customers can maximize the potential of their machines and address any issues that may arise during operation.

The availability of these high-quality red brick making machines comes at a time when the construction industry is experiencing a significant boom. With an increasing number of infrastructure and real estate projects, there is a growing need for reliable and efficient brick making equipment.

The announcement of the sale of red brick making machines by [Company] is sure to be welcomed by construction companies and contractors looking to upgrade their production capabilities. By investing in these advanced machines, they can enhance their operations and meet the demands of a rapidly expanding market.

In conclusion, the availability of top-of-the-line red brick making machines from [Company] represents a significant opportunity for the construction industry. With their focus on quality, efficiency, and sustainability, these machines are poised to make a positive impact on the production of red bricks for years to come. For more information on [Company]'s red brick making machines, interested parties are encouraged to visit their website or contact their sales team directly.

Company News & Blog

High-Quality Brick Making Machines for Sale: Find Your Perfect Match Now!

Brick Making Machines For Sale: Revolutionizing the Construction IndustryThe global construction industry has been undergoing a significant transformation in recent years, with a growing emphasis on sustainable and cost-effective building materials. In line with this trend, the demand for advanced brick making machines has been steadily increasing, as more construction companies seek efficient and environmentally friendly solutions for producing high-quality bricks.Leading the way in this innovation is [Company Name], a renowned manufacturer of state-of-the-art brick making machines. With a rich history of over [X] years in the industry, the company has earned a solid reputation for delivering cutting-edge equipment that meets the diverse needs of its customers.In response to the escalating demand for its products, [Company Name] has announced the availability of its latest range of brick making machines for sale. These machines are designed to cater to the requirements of both small-scale and large-scale brick production, offering a wide array of features and capabilities to enhance productivity and quality.One of the key highlights of [Company Name]'s brick making machines is their advanced technological features. Equipped with precision-engineered components and automated systems, these machines are capable of producing bricks with exceptional accuracy and consistency. This not only ensures a superior finished product but also minimizes wastage and optimizes resource utilization.Moreover, [Company Name]'s brick making machines are designed with a strong focus on sustainability. By incorporating energy-efficient processes and eco-friendly materials, the machines significantly reduce carbon emissions and environmental impact. This aligns with the growing global emphasis on sustainable construction practices and positions [Company Name] as a frontrunner in promoting green manufacturing solutions.In addition to their technical prowess, [Company Name]'s brick making machines are known for their robust build and longevity. Constructed with high-grade materials and subjected to rigorous quality standards, these machines are built to withstand the rigors of continuous operation, ensuring long-term reliability and durability. This is a crucial factor for construction companies seeking to make sound investments in efficient and low-maintenance equipment.As part of its commitment to customer satisfaction, [Company Name] offers comprehensive support and after-sales service for its brick making machines. This includes technical assistance, maintenance programs, and spare parts availability, ensuring that customers can maximize the performance and lifespan of their equipment.With its extensive experience and track record of success, [Company Name] has established a strong global presence, serving a diverse clientele across various regions. The company's dedication to innovation, quality, and customer-centric solutions has positioned it as a trusted partner for construction companies seeking reliable and efficient brick making machines.The availability of [Company Name]'s latest brick making machines for sale presents a compelling opportunity for construction companies to upgrade their production capabilities and stay ahead in the competitive market. By investing in these advanced machines, businesses can enhance their operational efficiency, reduce costs, and contribute to sustainable building practices.In conclusion, the launch of [Company Name]'s new range of brick making machines for sale represents a significant milestone in the evolution of the construction industry. With its focus on advanced technology, sustainability, and customer support, [Company Name] is poised to make a substantial impact on the way bricks are produced, setting new standards for quality, efficiency, and environmental responsibility. As the demand for high-quality, eco-friendly bricks continues to rise, [Company Name] stands ready to meet the needs of construction companies worldwide, driving positive change and progress in the built environment.

High-quality Vacuum Extruder for Clay Brick: A Game-Changer for the Brick-Making Industry

Vacuum Extruder For Clay Brick, A Game Changer in Construction IndustryIn a recent development in the construction industry, a new vacuum extruder for clay brick has been introduced, promising to revolutionize the way bricks are made. The innovation behind this vacuum extruder is set to significantly improve efficiency, quality, and sustainability in brick production.The vacuum extruder, developed by a leading construction machinery manufacturer, is designed to optimize the production process of clay bricks. By integrating cutting-edge technology and a meticulous engineering approach, the vacuum extruder offers a range of benefits that are set to redefine the industry standards.One of the main advantages of the vacuum extruder is its ability to remove excess moisture from the clay mixture before the extrusion process. This results in a more uniform and solid brick, with less risk of cracking or distortion during the drying and firing stages. As a result, the vacuum extruder is expected to improve the overall quality and durability of clay bricks, making them more suitable for a wider range of construction applications.Furthermore, the vacuum extruder is also a game changer in terms of production efficiency. By optimizing the extrusion and shaping process, the machine can significantly increase the output of high-quality clay bricks, while reducing the production time and labor costs. This means that construction companies can produce more bricks in a shorter amount of time, ultimately leading to higher profitability and competitiveness in the market.In addition to its performance benefits, the vacuum extruder also offers significant sustainability advantages. By using a vacuum to remove excess moisture from the clay mixture, the machine consumes less energy during the drying and firing stages of brick production. This not only reduces the overall carbon footprint of the production process but also lowers the operational costs for construction companies.The introduction of the vacuum extruder comes at a time when the construction industry is increasingly focused on sustainability and efficiency. With the global demand for environmentally friendly and high-quality building materials on the rise, the vacuum extruder is well positioned to meet these market needs and set new standards for brick production.In light of these advancements, it is no surprise that the vacuum extruder has already garnered significant attention from construction companies and industry professionals. With its potential to transform the way clay bricks are made, the machine represents a major step forward in the construction industry.As one of the leading construction machinery manufacturers, {} has always been at the forefront of innovation and technological advancement. With a strong commitment to research and development, the company has consistently delivered groundbreaking solutions that have redefined industry standards.The introduction of the vacuum extruder for clay brick is a testament to the company's dedication to pushing the boundaries of what is possible in construction machinery. By combining cutting-edge technology with a deep understanding of industry needs, {} has once again demonstrated its ability to drive innovation and bring about positive change in the construction sector.Looking ahead, the vacuum extruder is poised to make a significant impact on the construction industry, offering a new standard of quality, efficiency, and sustainability in brick production. As construction companies continue to seek improved building materials and production processes, the vacuum extruder is set to play a crucial role in shaping the future of the industry. With its potential to transform the way clay bricks are made, the vacuum extruder has undoubtedly set a new benchmark for excellence in construction machinery.

Innovative Brick Extruder Technology: An Overview

Brick Extruder Revolutionizes Construction IndustryThe construction industry has seen a major shift in recent years with the introduction of innovative technologies that have streamlined the building process. One such technology that has been making waves in the industry is the Brick Extruder, a state-of-the-art machine that has the ability to revolutionize the way bricks are produced and used in construction.The Brick Extruder, developed by a leading construction equipment manufacturer, is a cutting-edge machine that is changing the way bricks are manufactured. Traditional brick-making processes involve a labor-intensive and time-consuming method of mixing the raw materials, compressing the mixture, and then baking the bricks in a kiln. This method not only requires a large amount of energy and resources but also takes a significant amount of time to produce the final product.The Brick Extruder, on the other hand, automates the entire process, making it faster, more efficient, and environmentally friendly. The machine is capable of mixing the raw materials, shaping the bricks, and extruding them in a continuous process, significantly reducing the time and resources required for brick production. Additionally, the Brick Extruder is designed to produce bricks of uniform size and shape, ensuring high-quality and consistent building materials for construction projects.One of the key features of the Brick Extruder is its versatility. The machine is capable of producing a wide range of brick types, including solid bricks, hollow bricks, perforated bricks, and even special-shaped bricks, giving construction companies the flexibility to meet various project requirements. This adaptability makes the Brick Extruder an ideal solution for both small-scale and large-scale construction projects, providing companies with the ability to produce custom bricks for a variety of building applications.In addition to its operational efficiency, the Brick Extruder also boasts environmental benefits. The machine is designed to reduce waste and optimize the use of raw materials, resulting in minimal environmental impact. By streamlining the brick-making process and minimizing the reliance on traditional kiln firing, the Brick Extruder helps to conserve energy and lower carbon emissions, making it an eco-friendly option for sustainable construction practices.Furthermore, the Brick Extruder is equipped with advanced technology and automation features that improve productivity and reduce labor costs. The machine's user-friendly interface and automated controls make it easy to operate, requiring minimal manual intervention and supervision. This not only increases production efficiency but also reduces the need for skilled labor, making the Brick Extruder a cost-effective solution for construction companies.The introduction of the Brick Extruder marks a significant advancement in the construction industry, offering a modern and efficient approach to brick manufacturing. With its ability to streamline the production process, provide high-quality bricks, and reduce environmental impact, the Brick Extruder is poised to revolutionize the way construction materials are manufactured and utilized.As construction companies continue to seek innovative solutions to improve their operations and meet the demands of modern building projects, the Brick Extruder stands out as a game-changing technology that is reshaping the industry. With its potential to drive efficiency, sustainability, and cost-effectiveness, the Brick Extruder is set to make a lasting impact on the future of construction.

Explore a range of brick making machines: fly ash, cement, clay and more

Title: Revolutionizing the Construction Industry with Brick Making MachinesIntroduction:In today's era of rapid urbanization and infrastructural development, the demand for high-quality bricks is soaring. To meet this demand efficiently and sustainably, the construction industry has turned to advanced technologies such as brick making machines. These innovative machines have greatly revolutionized the brick-making process by offering numerous benefits, including faster production, cost-effectiveness, environmental sustainability, and the ability to produce bricks with diverse materials. In this blog, we will delve deeper into the advantages of brick making machines while highlighting their key features and the different types available in the market.Keywords: Brick Making Machine, Fly Ash Brick Making Machine, Bricks Machine, Cement Brick Making Machine, Clay Brick Making Machine, Concrete Block Making MachineBody:1. Overview of Brick Making Machines:Brick making machines are mechanical devices designed to manufacture bricks of various shapes, sizes, and compositions. They have become an indispensable part of the construction industry due to their versatility, efficiency, and ability to meet varying demands. These machines automate the process of brick production, reducing manual labor, improving productivity, and ensuring consistent quality.2. Key Features and Advantages:2.1 Faster Production:Brick making machines significantly accelerate the production process compared to traditional methods. They have the capacity to manufacture hundreds or even thousands of bricks per hour, allowing for timely completion of construction projects.2.2 Cost-effectiveness:By automating the brick-making process, these machines minimize labor costs and boost overall efficiency. Additionally, the decreased dependency on human intervention reduces the chances of errors, resulting in higher productivity and cost savings.2.3 Environmental Sustainability:With growing environmental concerns, brick making machines have evolved to utilize alternative materials such as fly ash, cement, clay, and concrete. By utilizing fly ash (a byproduct of coal combustion), these machines contribute towards sustainable development by reducing the accumulation of industrial waste while producing durable bricks.2.4 Diverse Material Usage:Brick making machines offer the flexibility to work with various raw materials, allowing manufacturers to adapt to changing market trends and customer preferences. Whether it's traditional clay bricks, fly ash bricks, cement bricks, or concrete blocks, these machines provide the versatility to accommodate different materials.3. Different Types of Brick Making Machines:3.1 Fly Ash Brick Making Machine:Fly ash brick making machines are ideal for utilizing waste materials in the form of fly ash. They efficiently convert this waste into sturdy bricks, offering superior strength, durability, and thermal insulation properties. Moreover, they require less cement composition, resulting in cost savings and reduced environmental impact.3.2 Cement Brick Making Machine:Cement brick making machines produce high-quality bricks by blending cement, sand, and other aggregates. They offer excellent compressive strength and are commonly used for constructing walls, pavements, and other vertical structures.3.3 Clay Brick Making Machine:Clay brick making machines use clay as the primary raw material. These machines employ hydraulic or mechanical pressure to shape the clay into bricks. Clay bricks are known for their aesthetic appeal, durability, and excellent thermal insulation properties.3.4 Concrete Block Making Machine:Concrete block making machines are designed for producing hollow or solid blocks using a mixture of cement, sand, stone chips, and water. They are widely used in construction projects due to their remarkable strength, load-bearing capacity, and fire resistance.Conclusion:Brick making machines have undoubtedly brought a revolution in the construction industry. These machines serve as a game-changer by streamlining the brick-making process, ensuring cost-effectiveness, and promoting environmental sustainability. Manufacturers, suppliers, and dealers worldwide are now offering a diverse range of brick making machines including fly ash brick making machines, cement brick making machines, clay brick making machines, and concrete block making machines, catering to the evolving needs of the industry. Embracing these advanced technologies is undoubtedly a step towards a brighter and more environmentally conscious future in the construction sector.Keywords: Brick Making Machine, Fly Ash Brick Making Machine, Bricks Machine, Cement Brick Making Machine, Clay Brick Making Machine, Concrete Block Making Machine

Highly Efficient Vacuum Brick Making Machine for Your Construction Business

Vacuum Brick Making Machine Revolutionizes Brick ProductionIn the world of construction, bricks are an essential building material that has been used for centuries. However, the traditional method of making bricks can be time-consuming and labor-intensive. That is until now, with the introduction of the revolutionary Vacuum Brick Making Machine by a leading construction machinery company.This groundbreaking machine has changed the game for brick production by utilizing the power of vacuum technology to create high-quality bricks with unparalleled efficiency. By removing the air and excess moisture from the clay material, the Vacuum Brick Making Machine has been able to produce bricks that are stronger, more durable, and of higher quality than those made through traditional methods.The Vacuum Brick Making Machine has also significantly increased productivity, as it can produce a large number of bricks in a fraction of the time it would take using traditional brick-making techniques. With its automated system and precise molding capabilities, it has reduced the need for manual labor, making brick production more cost-effective for construction companies.The company behind this groundbreaking innovation has been a leader in the construction machinery industry for over two decades. With a strong focus on research and development, they have continuously strived to create innovative solutions to improve construction processes and enhance the quality of construction materials.Their Vacuum Brick Making Machine is the latest product to showcase their commitment to innovation and excellence in the construction equipment market. With its advanced technology and superior performance, this machine has quickly become a game-changer for the brick production industry.One of the key features of the Vacuum Brick Making Machine is its versatility. It can produce a wide variety of bricks, including solid, hollow, and interlocking bricks, making it suitable for a range of construction projects. In addition, the machine is also capable of producing bricks in different sizes and shapes, allowing for greater customization and flexibility in design.Furthermore, the Vacuum Brick Making Machine has been designed with environmental sustainability in mind. By reducing the need for excessive water and energy consumption in the brick-making process, it has significantly lowered the carbon footprint of brick production, making it a more eco-friendly option for construction companies.The company has also provided comprehensive training and support for the installation and maintenance of the Vacuum Brick Making Machine to ensure that its customers can maximize its performance and longevity. This commitment to customer satisfaction has solidified their reputation as a trusted partner for construction companies looking to streamline their production processes.The introduction of the Vacuum Brick Making Machine has already made a significant impact on the construction industry, with many companies adopting this innovative technology to improve their brick production capabilities. As a result, the demand for this machine has been steadily increasing, and it has quickly become a must-have investment for construction companies looking to stay ahead of the competition.With its remarkable efficiency, precision, and environmental benefits, the Vacuum Brick Making Machine has set a new standard for brick production, and it is poised to reshape the future of construction materials. As the company continues to innovate and refine its technologies, it is clear that the Vacuum Brick Making Machine is just the beginning of a new era in brick production.In conclusion, the Vacuum Brick Making Machine has revolutionized the way bricks are produced, setting a new benchmark for quality, efficiency, and sustainability in the construction industry. With its advanced technology and proven performance, it is no surprise that this innovative machine has quickly become a game-changer for construction companies worldwide. As construction projects continue to evolve and demand for high-quality building materials grows, the Vacuum Brick Making Machine is undoubtedly at the forefront of shaping the future of brick production.

Discover the Latest Clay Brick Making Machine for Sale in China

China Clay Brick Making Machine, a leading manufacturer of brick making machines in China, is revolutionizing the construction industry with its innovative and efficient brick making machines. With a strong emphasis on technology and research, the company has made significant advancements in the field of brick making, providing high-quality machines to clients all over the world.The company's brick making machines are designed to meet the diverse needs of the construction industry, with a focus on producing high-quality bricks that are durable and long-lasting. The company's commitment to quality and innovation has made it a trusted name in the industry, with its machines being used in construction projects of all sizes, from small-scale residential buildings to large commercial developments.One of the key features of China Clay Brick Making Machine's machines is their versatility and efficiency. The machines are capable of producing a wide range of brick sizes and shapes, allowing for flexibility in design and construction. This versatility is particularly valuable in today's construction industry, where architects and builders are constantly pushing the boundaries of traditional brick design.In addition to their versatility, China Clay Brick Making Machine's machines are also known for their high level of automation and efficiency. The company has continuously invested in research and development to develop cutting-edge technologies that streamline the brick making process, increasing productivity and reducing labor costs for their clients. This commitment to innovation has made their machines highly sought after in the industry, with clients consistently praising their reliability and high performance.Moreover, the company's commitment to sustainability and environmental responsibility sets them apart in the industry. China Clay Brick Making Machine prioritizes the use of sustainable materials and energy-efficient technologies in their machines, ensuring that their production processes have minimal impact on the environment. This emphasis on sustainability has made their machines a popular choice for environmentally-conscious builders and developers, who are increasingly seeking out eco-friendly construction solutions.With a strong emphasis on customer satisfaction, China Clay Brick Making Machine also provides comprehensive support and training for their clients. The company's team of experts is dedicated to helping clients get the most out of their machines, providing training, technical support, and ongoing maintenance services to ensure that their machines continue to perform at the highest level for years to come.In addition to their commitment to quality and innovation, China Clay Brick Making Machine has also established a strong reputation for reliability and professionalism in the industry. The company's machines are known for their durability and low maintenance requirements, making them a cost-effective choice for builders and developers looking to invest in long-term, reliable brick making solutions.Furthermore, China Clay Brick Making Machine's dedication to excellence has earned them a loyal client base and a strong international presence. The company's machines are used in construction projects around the world, with a particularly strong presence in emerging markets where there is growing demand for high-quality, efficient brick making solutions.In conclusion, China Clay Brick Making Machine is a leading manufacturer of brick making machines, known for their commitment to quality, innovation, and sustainability. With a strong focus on technology and research, the company has developed cutting-edge machines that are versatile, efficient, and environmentally friendly. Their dedication to customer satisfaction and reliability has made them a trusted name in the industry, with a strong international presence and a loyal client base. As the construction industry continues to evolve, China Clay Brick Making Machine is well-positioned to continue leading the way with its innovative and high-performance brick making machines.

Top Brick Making Machine for Sale: Find the Best Deals Now

With the growing demand for sustainable construction materials, the development of eco-friendly brick-making machines has gained significant attention in the industry. One company at the forefront of this innovation is based in {company location}, which has recently introduced a state-of-the-art brick making machine designed to produce high-quality, environmentally friendly bricks.The {company name} is a leading manufacturer of construction machinery with a strong focus on sustainable and eco-friendly solutions. The company has been a pioneer in developing advanced technologies for brick making, and its latest offering is set to revolutionize the way bricks are produced.The new brick making machine incorporates innovative features that set it apart from traditional brick making processes. It utilizes advanced technology to minimize waste and reduce energy consumption, making it a highly efficient and sustainable option for brick production. In addition, the machine is designed to produce bricks of superior quality, with uniform dimensions and excellent strength.One of the key advantages of the {company name} brick making machine is its versatility. It can be used to produce a wide range of bricks, including interlocking bricks, hollow bricks, and solid bricks, making it suitable for various construction applications. This level of flexibility makes it a valuable investment for construction companies and builders looking for reliable and cost-effective brick production solutions.Furthermore, the {company name} brick making machine is designed with user convenience in mind. It features a user-friendly interface and automated controls, allowing for easy operation and maintenance. This makes it ideal for both large-scale production facilities and smaller-scale operations, enabling businesses of all sizes to benefit from its advanced capabilities.In line with its commitment to sustainability, the {company name} has also focused on ensuring that its brick making machine has minimal environmental impact. The machine is engineered to minimize emissions and reduce the overall carbon footprint of brick production, aligning with global efforts to promote green and eco-friendly construction practices.The introduction of the {company name} brick making machine is a significant step forward in the quest for sustainable construction technologies. By providing an innovative and efficient solution for brick production, the company is contributing to the industry's transition towards more environmentally friendly practices.In addition to its focus on sustainability, the {company name} is renowned for its dedication to customer satisfaction. The company offers comprehensive support services for its brick making machine, including installation, training, and ongoing technical assistance. This ensures that customers can maximize the benefits of the machine while receiving the necessary support to maintain its optimal performance.As the demand for sustainable building materials continues to grow, the {company name} is well-positioned to meet the needs of the construction industry with its advanced brick making machine. By delivering a solution that combines efficiency, quality, and environmental responsibility, the company is poised to make a significant impact on the future of brick production.In conclusion, the {company name} has introduced a cutting-edge brick making machine that reflects its commitment to innovation, sustainability, and customer satisfaction. With its advanced technology, versatility, and environmental considerations, the machine is set to become a game-changer in the brick production industry, offering a reliable and eco-friendly solution for construction projects around the world.

Highly Efficient Automatic Block Making Machine for Your Business Needs

In a world where technology is constantly evolving and advancing, the construction industry is no exception. The introduction of Automatic Block Making Machine has revolutionized the way blocks are produced, making the process more efficient and cost-effective. This new technology is set to transform the construction industry, offering a range of benefits for companies looking to streamline their operations and improve productivity.The Automatic Block Making Machine is a state-of-the-art piece of equipment that is designed to automate the production of concrete blocks. It uses advanced technology to mold and compress concrete into specific shapes and sizes, with minimal human intervention required. This not only reduces labor costs but also ensures consistency and precision in the production process, resulting in high-quality blocks that meet industry standards.One of the key advantages of the Automatic Block Making Machine is its ability to increase production output significantly. With its automated operation, the machine can produce a large volume of blocks in a fraction of the time it would take using traditional methods. This means that construction companies can meet tight project deadlines and fulfill large orders with ease, ultimately improving their overall efficiency and profitability.In addition to its impressive production capabilities, the Automatic Block Making Machine also offers versatility in block design. With interchangeable molds, the machine can produce a variety of block shapes and sizes to meet the specific requirements of different construction projects. This flexibility is invaluable for companies that work on a wide range of building developments and need to adapt their block production accordingly.Moreover, the Automatic Block Making Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and built-in diagnostics system allow operators to monitor and adjust the production process with minimal training. This not only reduces the risk of errors and downtime but also ensures that the machine operates at peak performance consistently.The introduction of the Automatic Block Making Machine comes from [Company Name], a leading manufacturer of construction equipment known for its innovative solutions and commitment to quality. With years of experience in the industry, [Company Name] has a deep understanding of the challenges and demands faced by construction companies, and it has developed the Automatic Block Making Machine as a response to these needs.[Company Name] takes pride in its dedication to research and development, investing in cutting-edge technology to create products that push the boundaries of what is possible in the construction industry. The Automatic Block Making Machine is a testament to this approach, as it represents a leap forward in block production technology, setting new standards for efficiency and performance.In line with its commitment to customer satisfaction, [Company Name] provides comprehensive support for the Automatic Block Making Machine, including installation, training, and after-sales service. This ensures that companies can integrate the machine seamlessly into their operations and maximize its benefits without any downtime or disruption.The launch of the Automatic Block Making Machine is a game-changer for the construction industry, offering a smart and sustainable solution for block production. With its advanced technology, high production output, and user-friendly design, this machine is set to transform the way blocks are made, setting a new benchmark for efficiency and quality in construction.In conclusion, the Automatic Block Making Machine is a remarkable advancement that is poised to revolutionize the construction industry. With its unparalleled production capabilities, versatility in block design, and user-friendly features, this machine is a game-changer for companies looking to improve efficiency and productivity. Backed by [Company Name]'s expertise and commitment to quality, the Automatic Block Making Machine is set to redefine the standard for block production and elevate the construction industry to new heights.

Efficient and Advanced Brick Manufacturing Techniques for Increased Productivity

Breaking News: Automatic Brick Manufacturing Revolutionizes Construction Industry The construction industry is about to undergo a revolutionary transformation with the introduction of automatic brick manufacturing technology. The new technology, developed by a leading construction equipment manufacturer, has the potential to dramatically increase the efficiency and quality of brick production, leading to significant cost savings for construction companies around the world.The company, {} is a pioneer in the development of advanced construction equipment and has a long-standing reputation for delivering innovative solutions to the industry. With the introduction of their automatic brick manufacturing technology, they are once again demonstrating their commitment to driving progress and innovation in the construction sector.The new automatic brick manufacturing technology is capable of producing bricks at a rate that far exceeds traditional brick-making methods. By automating the entire production process, from raw material preparation to brick formation and curing, the technology is able to significantly increase production output while maintaining the highest standards of quality and consistency.One of the key advantages of the automatic brick manufacturing technology is its ability to reduce the reliance on manual labor. By automating the production process, construction companies can significantly reduce their labor costs while also minimizing the risk of human error. This not only leads to cost savings but also improves overall worker safety and reduces the physical strain on employees.In addition to the cost and efficiency benefits, the new technology also has a positive impact on the environmental sustainability of brick production. By optimizing the use of raw materials and energy, the technology is able to minimize waste and reduce the carbon footprint of brick manufacturing. This aligns with the growing demand for sustainable construction practices and positions the company as a leader in environmentally conscious manufacturing.The introduction of automatic brick manufacturing technology is expected to have a significant impact on the construction industry as a whole. By streamlining the brick production process and increasing efficiency, construction companies will be able to complete projects more quickly and cost-effectively. This, in turn, will lead to a more competitive industry and ultimately benefit consumers by driving down the cost of construction.Furthermore, the new technology has the potential to create new opportunities for job growth within the construction sector. While it may reduce the need for manual labor in brick production, it also opens up new roles in the operation and maintenance of the automated manufacturing equipment. This will help to drive innovation and skill development within the industry, ensuring a strong and dynamic workforce for the future.The introduction of automatic brick manufacturing technology by {} represents a significant milestone in the ongoing evolution of the construction industry. As construction companies continue to seek ways to improve efficiency, reduce costs, and embrace sustainable practices, this new technology has the potential to revolutionize the way bricks are produced and utilized in construction projects.The company’s commitment to innovation and excellence has once again solidified its position as a leader in the construction equipment industry. With the introduction of automatic brick manufacturing technology, they are setting a new standard for efficiency, quality, and sustainability in brick production, and paving the way for a brighter future for the construction industry as a whole.As the industry embraces and adopts this cutting-edge technology, the construction landscape is sure to be transformed in ways that were previously unimaginable. The introduction of automatic brick manufacturing technology marks a new era for construction, one that is defined by efficiency, sustainability, and progress. With {} leading the way, the future of construction looks brighter than ever before.

Ultimate Guide to Boosting Productivity with Block Industry Machines

Block Industry Machine Launches New, High-Efficiency Concrete Mixing EquipmentBlock Industry Machine has recently launched a new, high-efficiency concrete mixing equipment. The newly developed machine is designed to provide excellent performance, ease of operation, and energy efficiency, making it the perfect tool for construction and building industry workers.According to the company's introduction, Block Industry Machine is a leading manufacturer of high-quality block-making machines and other construction machinery. With more than 20 years of experience in the industry, the company has earned a stellar reputation for providing top-notch equipment that meets the needs of its clients.The newly launched concrete mixing equipment was developed through extensive research and development efforts by the company's team of experts. The machine is designed to be durable, user-friendly, and able to produce high-quality concrete with minimal waste, saving construction companies time and money.The new equipment features an innovative mixing system that ensures consistent concrete mixing, without any lumps or unevenness. A specially designed hopper system prevents materials from sticking, ensuring that materials can be loaded into the machine quickly and easily.Other features of the new concrete mixing equipment include a high-powered motor that facilitates fast mixing, as well as an automatic lubrication system that keeps the machine running smoothly and reduces downtimes.The machine is easy to operate, with an intuitive control panel that allows users to mix concrete according to their specific needs and preferences. Additionally, it is equipped with a variety of safety features to ensure that operators can work safely and comfortably.With the new concrete mixing equipment, Block Industry Machine has once again demonstrated its commitment to providing clients with top-of-the-line construction equipment that improves productivity, reduces waste, and increases profitability."Our new concrete mixing equipment is a game-changer for the construction industry," said a company spokesperson. "We have engineered the machine to be highly efficient and easy to use, allowing construction companies to get more done in less time. We are confident that the new equipment will be popular with our customers and that it will help them take their businesses to the next level."In conclusion, Block Industry Machine's launch of their new concrete mixing equipment is set to revolutionize the construction industry. The machine offers unparalleled efficiency, user-friendliness, and safety features to ensure that operators are comfortable and confident in their work. The launch once again affirms the company's dedication to providing top-quality construction equipment that meets the evolving needs of its clients.