Efficient Face Brick Making Machine for Your Construction Needs

By:Admin

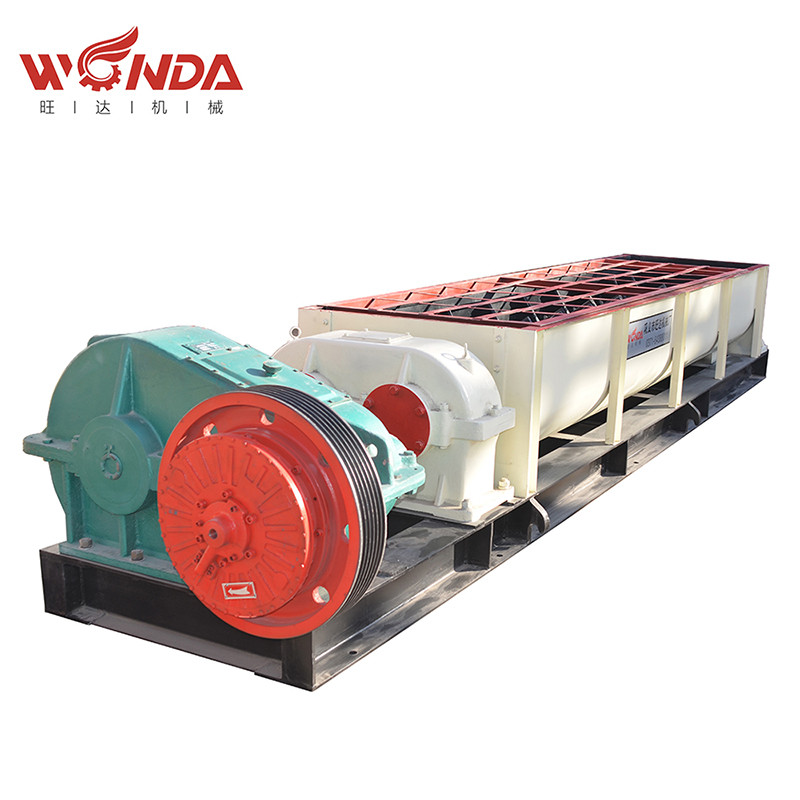

The face brick making machine, developed by an industry-leading company, is designed to meet the growing demand for sustainable construction materials. By using advanced technology and durable materials, this machine is able to produce face bricks with superior strength and durability, meeting or exceeding industry standards. This is a game-changer for construction companies looking to meet strict building codes and provide long-lasting, aesthetically pleasing structures for their clients.

One of the key features of this face brick making machine is its ability to produce bricks with a variety of textures and colors. This means that builders and architects are no longer limited to a handful of options when it comes to face bricks. With this machine, they can create a virtually endless array of designs and styles, allowing for greater creativity and customization in their projects.

Furthermore, the face brick making machine is incredibly efficient, reducing waste and minimizing the environmental impact of brick production. It utilizes a precise batching system and state-of-the-art mixing technology to ensure that each brick is uniform and free of defects. This not only saves time and money for construction companies, but also helps to conserve natural resources and reduce the carbon footprint of building projects.

In addition to its advanced capabilities, the face brick making machine is also designed with user-friendliness in mind. It features a user-friendly interface and intuitive controls, making it easy for operators to produce high-quality bricks with minimal training. This ensures that construction companies can quickly integrate this technology into their production processes and start reaping the benefits right away.

At the heart of this cutting-edge machine is a commitment to sustainability and innovation. The company behind the face brick making machine is dedicated to finding new and better ways to build, and their technology reflects that ethos. By providing a smarter, more sustainable alternative to traditional brick production, they are helping to shape the future of construction and set a new standard for industry practices.

With its advanced technology, customizable options, and focus on sustainability, the face brick making machine is quickly becoming a must-have tool for construction companies around the world. It is revolutionizing the way face bricks are produced, offering a more efficient, cost-effective, and eco-friendly solution for meeting the demands of modern construction projects.

In conclusion, the face brick making machine developed by this industry-leading company is a game-changer for the construction industry. Its innovative technology, customizable options, and sustainable design make it an essential tool for any builder or architect looking to create high-quality, environmentally friendly structures. By investing in this cutting-edge technology, construction companies can stay ahead of the curve and set new standards for excellence in the industry.

Company News & Blog

Compact Brick Making Machine Takes the Construction Industry by Storm

Mini Brick Making Machine: A New Era of Sustainable and Efficient ConstructionThe construction industry has seen significant changes in the past years, not only in terms of the technologies used but also in terms of the focus on sustainability and efficiency. From green energy solutions to the adoption of eco-friendly construction materials, the industry is continuously exploring innovative ways to minimize environmental impact and optimize productivity. In line with this pursuit for progress, a new player is entering the scene – the Mini Brick Making Machine (MBMM). This innovative machine is poised to revolutionize the way we build structures, bringing about a new era of sustainable and efficient construction.What is the Mini Brick Making Machine?The Mini Brick Making Machine is a compact, portable machine that is used to manufacture bricks on-site. It is suitable for small to medium-sized construction projects such as homes, commercial buildings, and even road works. It is powered by electrical motors, which makes it environmentally friendly and cost-efficient. The machine is designed to produce up to 1000 bricks per hour, which means faster delivery and reduced construction time. It is also easy to operate, with a user-friendly interface that can be operated by just one person.The Advantages of Using the Mini Brick Making MachineOne of the key advantages of using the Mini Brick Making Machine is its environmental friendliness. The machine is powered by electrical motors, which means that it doesn't produce any harmful emissions that can contribute to air pollution. This makes it a more sustainable and eco-friendly alternative to traditional brick-making methods, which rely heavily on fossil fuels and other non-renewable resources.Another advantage of using the Mini Brick Making Machine is its cost-efficiency. The machine eliminates the need for transporting bricks from one location to another, which can be costly and time-consuming. By producing bricks on-site, construction companies can save on transportation costs and reduce the delivery time of construction materials. This, in turn, can result in significant cost savings that can be passed on to clients.The Mini Brick Making Machine is also known for its high quality and durability. The machine is designed to produce bricks that are uniform in size and shape, which ensures that the finished construction is strong and sturdy. It is also made from high-quality materials that are built to withstand wear and tear, making it a reliable investment for construction companies.Company IntroductionThe company that manufactures the Mini Brick Making Machine is a family-owned business that has been operating for over 30 years. They specialize in the design, manufacturing, and distribution of construction equipment and machinery. The company prides itself on delivering high-quality products that are innovative, cost-efficient, and sustainable. They have a team of experienced engineers and technicians who are dedicated to ensuring that their products are at the forefront of construction technology.The Mini Brick Making Machine is just one of the many products that the company offers. They also provide a range of other construction equipment, including concrete mixers, vibrators, and scaffolding. All of their products are designed with the aim of helping construction companies achieve optimal productivity while minimizing environmental impact.ConclusionThe Mini Brick Making Machine is an exciting innovation in the construction industry, offering a more sustainable and efficient way of producing bricks. With its cost-efficiency, high quality, and ease of operation, the machine is poised to become a game-changer in the industry. Its environmental friendliness is also a huge advantage, making it a more sustainable alternative to traditional brick-making methods. With the backing of an experienced and dedicated company, the Mini Brick Making Machine will surely make waves in the construction industry, paving the way for a more sustainable and efficient future.

Efficient Brick Making Machine for Your Construction Needs

Auto Brick Machine Revolutionizes Brick Making ProcessThe brick making industry has experienced a revolutionary transformation with the introduction of the state-of-the-art Auto Brick Machine, a game-changing technology that has redefined the way bricks are manufactured. This innovative machine has been developed by a renowned company that has been an industry leader in providing cutting-edge solutions for the construction and building materials sector for over a decade.The Auto Brick Machine has significantly improved the efficiency and productivity of brick manufacturing by automating the entire process, from raw material mixing to brick molding and finally, the drying and firing stages. This groundbreaking technology eliminates the need for manual labor and streamlines the production process, resulting in a higher output and superior quality bricks.The company behind this groundbreaking innovation has a proven track record of delivering top-notch machinery and equipment to the construction industry. With a commitment to innovation and excellence, the company has continually invested in research and development to bring forward-thinking solutions to the market.The Auto Brick Machine is a testament to the company's dedication to advancing the brick-making industry and providing its customers with the tools they need to thrive in a competitive market. By leveraging cutting-edge technology and engineering expertise, the company has developed a machine that offers unparalleled performance, reliability, and versatility.One of the key features of the Auto Brick Machine is its ability to produce a wide range of brick sizes and shapes, catering to the diverse needs of construction projects. Whether it's standard bricks, interlocking bricks, or customized designs, this machine can efficiently manufacture them to meet the specific requirements of builders and contractors.Moreover, the machine is designed with user-friendly controls and a high degree of automation, making it easy to operate and maintain. This not only increases the efficiency of brick production but also reduces the need for skilled labor, ultimately driving down operational costs for brick manufacturers.In addition to its cutting-edge technology, the Auto Brick Machine is also engineered with a focus on sustainability and environmental responsibility. By optimizing energy consumption and minimizing waste generation, the machine embodies the company's commitment to eco-friendly manufacturing practices, aligning with global efforts to promote sustainable development in the construction industry.The impact of the Auto Brick Machine on the brick-making industry has been nothing short of transformative. Its introduction has ushered in a new era of efficiency, productivity, and quality in brick production, empowering manufacturers to meet the growing demand for high-quality bricks in the construction sector.As the construction industry continues to evolve and adapt to the demands of a rapidly changing world, the need for innovative solutions like the Auto Brick Machine has never been greater. This groundbreaking technology is not just a testament to the company's engineering prowess but also a testament to its commitment to driving progress in the construction and building materials sector.In conclusion, the Auto Brick Machine has set a new standard for brick manufacturing, offering a compelling combination of cutting-edge technology, superior performance, and environmental sustainability. As the company continues to push the boundaries of innovation, it is poised to make an even greater impact on the construction industry, driving positive change and delivering value to its customers around the world.

Top Quality Brick Machine Available in India: Find Out More

The brick making industry in India has seen a significant technological advancement with the introduction of advanced brick making machines. These machines have revolutionized the traditional brick making process and are helping to increase efficiency and productivity in the brick manufacturing sector.One of the key players in this industry is a company that has been at the forefront of developing innovative and high-quality brick making machines. With their state-of-the-art technology and commitment to research and development, they have become a trusted name in the brick making machinery market.The company's brick making machines are known for their robust construction, high efficiency, and user-friendly operation. They offer a wide range of machines that cater to the diverse needs of brick manufacturers, including automatic, semi-automatic, and manual machines. Their machines are also designed to produce various types of bricks such as concrete, clay, fly ash, and interlocking bricks.The brick making machines from this company are equipped with advanced features such as automatic material feeding, mold vibrating, and hydraulic pressing, which ensure consistent and high-quality brick production. These machines also have a high production capacity, allowing brick manufacturers to meet the growing demand for bricks in the construction industry.One of the key advantages of using these machines is their energy efficiency and cost-effectiveness. The company has incorporated energy-saving technologies in their machines, which not only reduce the overall operational costs but also contribute to environmental sustainability.Furthermore, the company provides comprehensive after-sales support to its customers, including installation, training, and maintenance services. This ensures that brick manufacturers can maximize the performance and lifespan of their machines, leading to long-term cost savings and operational efficiency.Recently, the company has launched a new range of brick making machines that are specifically tailored to the needs of the Indian market. These machines have been designed to address the challenges faced by brick manufacturers in India, such as the availability of raw materials, labor costs, and environmental regulations.The new range of machines incorporates innovative technologies that help reduce the usage of natural resources, minimize waste generation, and optimize the production process. Additionally, these machines are designed to be more compact and mobile, making them suitable for small-scale brick manufacturing operations in rural areas.The company has also expressed its commitment to supporting the Indian government's initiatives for promoting sustainable and eco-friendly construction practices. They are actively involved in research and development activities to create more advanced and environmentally friendly brick making machines that align with the government's vision for a cleaner and greener India.With the introduction of these advanced brick making machines, the Indian brick manufacturing industry is set to witness a significant transformation. These machines will not only improve the overall productivity and quality of bricks but also contribute to the sustainable development of the construction sector in India.In conclusion, the company's commitment to innovation and sustainability has positioned them as a leading provider of advanced brick making machines in India. Their machines are making a positive impact on the brick manufacturing industry by increasing efficiency, reducing costs, and promoting environmental responsibility. As the demand for high-quality bricks continues to rise in India, these advanced machines are expected to play a critical role in shaping the future of the brick making industry in the country.

Highly Efficient Vacuum Brick Making Machine for Your Construction Business

Vacuum Brick Making Machine Revolutionizes Brick ProductionIn the world of construction, bricks are an essential building material that has been used for centuries. However, the traditional method of making bricks can be time-consuming and labor-intensive. That is until now, with the introduction of the revolutionary Vacuum Brick Making Machine by a leading construction machinery company.This groundbreaking machine has changed the game for brick production by utilizing the power of vacuum technology to create high-quality bricks with unparalleled efficiency. By removing the air and excess moisture from the clay material, the Vacuum Brick Making Machine has been able to produce bricks that are stronger, more durable, and of higher quality than those made through traditional methods.The Vacuum Brick Making Machine has also significantly increased productivity, as it can produce a large number of bricks in a fraction of the time it would take using traditional brick-making techniques. With its automated system and precise molding capabilities, it has reduced the need for manual labor, making brick production more cost-effective for construction companies.The company behind this groundbreaking innovation has been a leader in the construction machinery industry for over two decades. With a strong focus on research and development, they have continuously strived to create innovative solutions to improve construction processes and enhance the quality of construction materials.Their Vacuum Brick Making Machine is the latest product to showcase their commitment to innovation and excellence in the construction equipment market. With its advanced technology and superior performance, this machine has quickly become a game-changer for the brick production industry.One of the key features of the Vacuum Brick Making Machine is its versatility. It can produce a wide variety of bricks, including solid, hollow, and interlocking bricks, making it suitable for a range of construction projects. In addition, the machine is also capable of producing bricks in different sizes and shapes, allowing for greater customization and flexibility in design.Furthermore, the Vacuum Brick Making Machine has been designed with environmental sustainability in mind. By reducing the need for excessive water and energy consumption in the brick-making process, it has significantly lowered the carbon footprint of brick production, making it a more eco-friendly option for construction companies.The company has also provided comprehensive training and support for the installation and maintenance of the Vacuum Brick Making Machine to ensure that its customers can maximize its performance and longevity. This commitment to customer satisfaction has solidified their reputation as a trusted partner for construction companies looking to streamline their production processes.The introduction of the Vacuum Brick Making Machine has already made a significant impact on the construction industry, with many companies adopting this innovative technology to improve their brick production capabilities. As a result, the demand for this machine has been steadily increasing, and it has quickly become a must-have investment for construction companies looking to stay ahead of the competition.With its remarkable efficiency, precision, and environmental benefits, the Vacuum Brick Making Machine has set a new standard for brick production, and it is poised to reshape the future of construction materials. As the company continues to innovate and refine its technologies, it is clear that the Vacuum Brick Making Machine is just the beginning of a new era in brick production.In conclusion, the Vacuum Brick Making Machine has revolutionized the way bricks are produced, setting a new benchmark for quality, efficiency, and sustainability in the construction industry. With its advanced technology and proven performance, it is no surprise that this innovative machine has quickly become a game-changer for construction companies worldwide. As construction projects continue to evolve and demand for high-quality building materials grows, the Vacuum Brick Making Machine is undoubtedly at the forefront of shaping the future of brick production.

Automated Brick Burning Equipment: A Game Changer for Construction Industry

[Company Name] Introduces New Brick Burning Machine to Revolutionize Production Process[City, State] - [Company Name], a leading provider of industrial machinery, has announced the release of their latest product: the Brick Burning Machine. This innovative machine is set to revolutionize the brick production process, offering increased efficiency and cost savings for brick manufacturers.The Brick Burning Machine is designed to streamline the brick burning process, which is a critical step in the production of high-quality bricks. Traditionally, this process has been time-consuming and labor-intensive, requiring significant manpower and resources. However, [Company Name] has developed a machine that automates and accelerates this process, allowing manufacturers to produce bricks at a much faster rate.One of the key features of the Brick Burning Machine is its advanced heating technology, which ensures that bricks are burned uniformly and consistently. This not only improves the quality of the end product but also reduces the risk of defects and wastage. In addition, the machine is equipped with a user-friendly interface, making it easy for operators to monitor and control the burning process."We are excited to introduce the Brick Burning Machine to the market," said [Spokesperson Name], CEO of [Company Name]. "This machine represents a significant advancement in brick production technology, and we believe it will have a major impact on the industry. We have already received enthusiastic feedback from our beta testers, and we are confident that this machine will help our customers increase their productivity and reduce their manufacturing costs."In addition to its innovative technology, the Brick Burning Machine is also designed with sustainability in mind. By optimizing the burning process, the machine helps to minimize energy consumption and reduce carbon emissions. This is an important consideration for brick manufacturers who are increasingly looking for ways to make their operations more environmentally friendly.The introduction of the Brick Burning Machine comes at a time when the demand for bricks is increasing, driven by growing construction activity around the world. With this machine, brick manufacturers will be able to meet this demand more efficiently and effectively, helping to address a key challenge in the industry.[Company Name] has a long history of delivering cutting-edge machinery to the industrial sector. Founded in [Year], the company has built a reputation for its commitment to innovation, quality, and customer satisfaction. The introduction of the Brick Burning Machine is the latest example of this commitment, and the company is already working on additional advancements in brick production technology."We are constantly looking for ways to improve our products and provide greater value to our customers," said [Spokesperson Name]. "The Brick Burning Machine is just one example of how we are leveraging our expertise to address the needs of the industry. We are excited to see the impact that this machine will have on our customers' operations."As the construction industry continues to grow, the demand for high-quality bricks will only increase. With the introduction of the Brick Burning Machine, [Company Name] is poised to play a pivotal role in meeting this demand, helping brick manufacturers around the world to enhance their production processes and achieve greater success.About [Company Name]:[Company Name] is a leading provider of industrial machinery, specializing in innovative solutions for the construction and manufacturing sectors. With a focus on quality, reliability, and sustainability, the company is committed to helping its customers improve their operations and achieve their business goals. For more information, visit [Company Website].

Top-Quality Brick, Roofing Tile and Wall Plant Manufacturing Services

Clay Brick Production Line: Revolutionizing the Construction IndustryThe construction industry has always been at the forefront of innovation and constant evolution. From architectural marvels to efficient building techniques, each new development caters to the ever-growing demands of the world's population. In this pursuit, the Clay Brick Production Line has emerged as a significant game-changer, offering unprecedented advantages in terms of efficiency, sustainability, and affordability. In this blog, we will delve into the intricacies of the Clay Brick Production Line and explore its impact on the construction industry.Before we delve into the production line, it is essential to understand the significance of clay bricks. Clay bricks have been a staple in construction for centuries, owing to their durability, strength, and versatility. Architects and builders have long relied on this traditional building material to erect long-lasting structures. However, with the advent of globalization and the rising demand for construction materials, the industry has witnessed a need for enhanced production capabilities. Enter the Clay Brick Production Line.The Clay Brick Production Line is a comprehensive and sophisticated system that encompasses the entire brick manufacturing process. From the initial preparation of clay to the packaging of finished products, this system ensures a smooth and efficient operation at every stage. One company, who specializes in this area, designs and manufactures bespoke Clay Brick Production Lines that cater to the unique needs and requirements of clients worldwide (brand name removed).The preparation stage of the production line is a critical component in ensuring the quality and consistency of the final product. High-quality clay is sourced and processed meticulously, removing any impurities or unwanted particles. The precisely controlled moisture content and particle size distribution guarantee optimal brick characteristics. This attention to detail during preparation sets the foundation for a successful and reliable production line.The extrusion stage is where the magic happens. The prepared clay is passed through an extruder, which shapes and molds the material into the desired brick form. This process can be fully automated, providing significant benefits in terms of efficiency and consistency. The extrusion stage also allows for customization, ensuring that each brick meets the specific requirements of the project at hand. The versatility and adaptability of the Clay Brick Production Line make it a valuable asset for any construction project.Once the bricks have been extruded, the cutting stage comes into play. Precise cutting techniques ensure that each brick is uniform in shape and size, guaranteeing seamless assembly during construction. Advanced machinery and cutting-edge technology minimize wastage and increase productivity. The Clay Brick Production Line also allows for the creation of various brick sizes and designs, providing architects and builders with unlimited possibilities for their creative vision.Packaging is the final step in the production line, ensuring the safe transportation and storage of the manufactured bricks. The Clay Brick Production Line offers customizable packaging solutions, tailored to individual project specifications. This attention to detail enables efficient logistics and reduces the risk of damage during transit, further cementing the advantages of this innovative system.The Clay Brick Production Line has revolutionized the construction industry in numerous ways. Firstly, efficiency is greatly enhanced due to automation and streamlined processes. With the ability to produce thousands of bricks per hour, the production line accelerates construction timelines, enabling builders to meet deadlines and complete projects promptly. Additionally, the reduced margin for error ensures consistent quality and minimizes rework, optimizing resource utilization.Another significant advantage of the Clay Brick Production Line lies in its sustainability credentials. Clay bricks are an inherently eco-friendly building material, and the automated production line enhances this attribute. Precise material control reduces waste, and optimized energy consumption makes the process highly energy-efficient. Furthermore, the longevity and durability of clay bricks contribute to the overall sustainability of constructed buildings.Affordability is also a key factor in the construction industry, and the Clay Brick Production Line delivers on this front as well. By streamlining processes and minimizing waste, the cost of production is substantially reduced. These cost savings can be passed on to builders and end-users, making clay bricks an attractive and accessible choice for construction projects of any scale.In conclusion, the Clay Brick Production Line has emerged as a groundbreaking solution that caters to the growing demands of the construction industry. With its comprehensive and efficient system, this production line ensures the production of high-quality clay bricks that meet the exact specifications of builders and architects worldwide. From preparation to extrusion, cutting, and packaging, every stage of the process is meticulously crafted to enhance efficiency, sustainability, and affordability. Embracing the Clay Brick Production Line is the key to revolutionizing the construction industry and building a sustainable future for generations to come.

The Ultimate Guide to Clay Brick Making Machines: Everything You Need to Know

In recent news, the {company name} has introduced a new Clay Brick Making Machine, which is set to revolutionize the brick manufacturing industry. This innovative machine boasts cutting-edge technology and precision engineering, promising to streamline the brick-making process and significantly improve productivity.The Clay Brick Making Machine is designed to cater to the growing demand for sustainable and high-quality building materials. With its advanced features and capabilities, it is poised to transform the way bricks are manufactured, offering a more efficient and cost-effective solution for construction projects.The machine is equipped with state-of-the-art components, including a high-capacity clay mixer, an automatic brick molding system, and a precision cutting mechanism. These features work in tandem to ensure consistent and uniform brick production, while minimizing waste and maximizing output.{Company name} is a leading manufacturer and supplier of construction machinery, with a proven track record of delivering innovative and reliable equipment to the industry. With over {number} of experience in the field, the company has gained a reputation for its commitment to quality and customer satisfaction.The introduction of the Clay Brick Making Machine further solidifies {company name}'s position as a pioneer in the construction machinery sector. By leveraging its expertise and technical know-how, the company has developed a machine that addresses the evolving needs of the brick manufacturing industry.According to {spokesperson name}, the CEO of {company name}, the Clay Brick Making Machine represents a significant milestone for the company. "We are proud to unveil this groundbreaking machine, which embodies our dedication to innovation and excellence. We believe that it will set a new standard for brick manufacturing, empowering our customers to achieve greater efficiency and profitability."The Clay Brick Making Machine is designed to cater to a wide range of applications, from small-scale brick production to large-scale industrial operations. Its versatility and adaptability make it an ideal choice for businesses looking to enhance their brick manufacturing capabilities.In addition to its advanced features, the Clay Brick Making Machine is also designed with sustainability in mind. It is equipped with energy-efficient components and is built to minimize environmental impact. This aligns with {company name}'s commitment to promoting sustainable practices within the construction industry.The introduction of the Clay Brick Making Machine is expected to generate significant interest within the construction sector. Its potential to streamline operations, reduce costs, and improve product quality makes it an attractive investment for brick manufacturers and construction companies alike.In conclusion, the Clay Brick Making Machine is a testament to {company name}'s dedication to driving innovation and progress within the construction machinery industry. With its cutting-edge technology and superior performance, it is set to redefine the standards for brick manufacturing, setting a new benchmark for quality, efficiency, and sustainability.

High-quality Vacuum Extruder for Clay Brick: A Game-Changer for the Brick-Making Industry

Vacuum Extruder For Clay Brick, A Game Changer in Construction IndustryIn a recent development in the construction industry, a new vacuum extruder for clay brick has been introduced, promising to revolutionize the way bricks are made. The innovation behind this vacuum extruder is set to significantly improve efficiency, quality, and sustainability in brick production.The vacuum extruder, developed by a leading construction machinery manufacturer, is designed to optimize the production process of clay bricks. By integrating cutting-edge technology and a meticulous engineering approach, the vacuum extruder offers a range of benefits that are set to redefine the industry standards.One of the main advantages of the vacuum extruder is its ability to remove excess moisture from the clay mixture before the extrusion process. This results in a more uniform and solid brick, with less risk of cracking or distortion during the drying and firing stages. As a result, the vacuum extruder is expected to improve the overall quality and durability of clay bricks, making them more suitable for a wider range of construction applications.Furthermore, the vacuum extruder is also a game changer in terms of production efficiency. By optimizing the extrusion and shaping process, the machine can significantly increase the output of high-quality clay bricks, while reducing the production time and labor costs. This means that construction companies can produce more bricks in a shorter amount of time, ultimately leading to higher profitability and competitiveness in the market.In addition to its performance benefits, the vacuum extruder also offers significant sustainability advantages. By using a vacuum to remove excess moisture from the clay mixture, the machine consumes less energy during the drying and firing stages of brick production. This not only reduces the overall carbon footprint of the production process but also lowers the operational costs for construction companies.The introduction of the vacuum extruder comes at a time when the construction industry is increasingly focused on sustainability and efficiency. With the global demand for environmentally friendly and high-quality building materials on the rise, the vacuum extruder is well positioned to meet these market needs and set new standards for brick production.In light of these advancements, it is no surprise that the vacuum extruder has already garnered significant attention from construction companies and industry professionals. With its potential to transform the way clay bricks are made, the machine represents a major step forward in the construction industry.As one of the leading construction machinery manufacturers, {} has always been at the forefront of innovation and technological advancement. With a strong commitment to research and development, the company has consistently delivered groundbreaking solutions that have redefined industry standards.The introduction of the vacuum extruder for clay brick is a testament to the company's dedication to pushing the boundaries of what is possible in construction machinery. By combining cutting-edge technology with a deep understanding of industry needs, {} has once again demonstrated its ability to drive innovation and bring about positive change in the construction sector.Looking ahead, the vacuum extruder is poised to make a significant impact on the construction industry, offering a new standard of quality, efficiency, and sustainability in brick production. As construction companies continue to seek improved building materials and production processes, the vacuum extruder is set to play a crucial role in shaping the future of the industry. With its potential to transform the way clay bricks are made, the vacuum extruder has undoubtedly set a new benchmark for excellence in construction machinery.

High-quality Clay Brick Making Machine for Sale - Find Out More!

In recent years, the construction industry has seen a significant increase in the demand for clay bricks. With the growing emphasis on eco-friendly and sustainable building materials, there has been a resurgence in the use of clay bricks for various construction projects. As a result, the demand for efficient and advanced clay brick making machines has also skyrocketed. In response to this demand, the renowned company {} has introduced a state-of-the-art clay brick making machine that is set to revolutionize the brick manufacturing industry.{} is a leading manufacturer of construction machinery and equipment, with a long-standing reputation for delivering high-quality products. The company is known for its commitment to innovation and its dedication to providing solutions that meet the evolving needs of the construction industry. With a strong focus on research and development, {} has continually worked towards developing cutting-edge technologies that optimize the production processes and improve the quality of construction materials.The newly introduced clay brick making machine by {} is the culmination of extensive research and development efforts. This machine is designed to streamline the brick manufacturing process and enhance the overall efficiency of production. With its innovative features and advanced technology, this machine is set to set new standards in the industry.One of the key features of the clay brick making machine is its high production capacity. The machine is capable of producing a large number of bricks in a relatively short period, making it an ideal choice for large-scale brick manufacturing operations. This high production capacity is made possible by the use of advanced automation and control systems, which enable the machine to operate at optimal efficiency levels.In addition to its impressive production capacity, the clay brick making machine also boasts a high level of precision and accuracy. The machine is equipped with cutting-edge machinery and tools that ensure the uniformity and consistency of the bricks being produced. This level of precision is crucial in ensuring the structural integrity and durability of the bricks, ultimately making them more reliable for construction purposes.Moreover, the clay brick making machine is designed with an emphasis on energy efficiency and environmental sustainability. The machine incorporates advanced technologies that minimize energy consumption and reduce environmental impact. By utilizing energy-efficient components and processes, this machine helps to lower the carbon footprint of brick manufacturing operations, making it a more sustainable choice for construction projects.Another notable aspect of the clay brick making machine is its user-friendly interface and intuitive controls. The machine is designed to be easy to operate, requiring minimal training for the personnel managing the production process. This user-friendly design enhances the overall efficiency of brick manufacturing operations and reduces the likelihood of errors or accidents.With the introduction of this cutting-edge clay brick making machine, {} has once again demonstrated its commitment to driving innovation in the construction industry. This machine represents a significant advancement in brick manufacturing technology and is set to have a profound impact on the industry as a whole. As the demand for clay bricks continues to rise, this machine is poised to play a key role in meeting that demand and setting new standards of quality and efficiency in brick production.

Revolutionize your Concrete Block Production with this Advanced Machine

Cement Concrete Block Making Machine Revolutionizes Construction IndustryWith the rising demand for efficient and cost-effective construction solutions, the Cement Concrete Block Making Machine has emerged as a game-changer in the industry. The machine, developed by a leading manufacturer in the construction equipment sector, has been designed to streamline the process of manufacturing high-quality concrete blocks, paving blocks, and interlocking blocks for various construction projects.The Cement Concrete Block Making Machine is equipped with advanced technology and features that enable it to produce a wide range of concrete products with precision and consistency. It offers a high level of automation, allowing for easy operation and minimal manual intervention, which is a significant advantage for construction companies looking to optimize their production processes.The machine is versatile and can be customized to meet the specific requirements of different construction projects. Whether it's producing standard concrete blocks for residential buildings or specialized paving blocks for urban infrastructure, the Cement Concrete Block Making Machine delivers superior performance and efficiency.In addition to its technological capabilities, the machine is also designed with sustainability in mind. It has been engineered to minimize energy consumption and reduce waste generation, contributing to a greener and more eco-friendly construction process.The company behind the Cement Concrete Block Making Machine, has a long-standing reputation for delivering innovative and high-quality construction equipment. With a strong focus on research and development, the company has continuously strived to push the boundaries of technological innovation in the construction industry. This commitment to excellence is reflected in the Cement Concrete Block Making Machine, which has set new standards for efficiency and productivity in the field.Furthermore, the company offers comprehensive support and assistance to its customers, ensuring that they receive the necessary training and guidance to maximize the potential of the Cement Concrete Block Making Machine. This includes technical training for operation and maintenance, as well as ongoing customer service and support to address any issues or concerns that may arise.The introduction of the Cement Concrete Block Making Machine marks a significant milestone in the construction industry, offering a solution that not only improves productivity and efficiency but also enhances the overall quality of concrete products used in building and infrastructure projects. With its advanced technology and sustainable design, the machine is poised to revolutionize the way construction companies approach concrete block manufacturing.As the construction industry continues to evolve and adapt to new demands and challenges, innovative solutions like the Cement Concrete Block Making Machine will play a crucial role in driving progress and shaping the future of construction. It represents a new era of automation and sustainability, empowering construction companies to meet the growing demand for high-quality concrete products while reducing their impact on the environment.In conclusion, the Cement Concrete Block Making Machine, with its advanced technology, customizable capabilities, and commitment to sustainability, is a testament to the company's dedication to delivering solutions that meet the evolving needs of the construction industry. As it gains traction in the market, the machine is set to become a staple in construction projects of all scales, ushering in a new standard of efficiency and excellence in the manufacturing of concrete blocks.